The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

3 - 6 J U N E 2 0 1 9

MADRID, SPAIN

The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

3 - 6 J U N E 2 0 1 9

MADRID, SPAIN

34

e

q

u

ip

m

e

n

t

equipment

To Stay Ahead of

the Curve, Keeping

Adherence to Traditions

For more than 120 years of its history, Izolyator plant has

produced more than 620,000 high-voltage bushings, operating

in the vast majority of power facilities in Russia and the CIS

countries, as well as in 30 countries of the world. Due to

active research and development activities, continuous

expansion of international relations both in business and in

engineering direction, the company is constantly improving

its products, offering perfect innovative solutions, which

provide the highest level of reliability.

INNOVATIVE

DEVELOPMENTS

The range of products manufac-

tured by the company includes over

360 high-voltage bushings (includ-

ing its versions) of various types

and voltage classes. In total, about

32 new bushing designs were devel-

oped within the past 2018. Among

them there were innovative products

not previously produced in Russia.

Since 2018, Russian power grids

have set a course for the transfer of

all major technological processes

to a new digital platform. Support-

ing the implementation of power

grid digitalization concept, Izolyator

started the development of a new

bushings line containing additional

power sources for connecting digital

diagnostic equipment. Such an op-

tion will undoubtedly be in demand

in the nearest future when retrofi t-

ting power transformers and old

circuit breakers without inbuilt diag-

nostic tools.

Design and construction of new

modern digital substations required

new types of high-voltage equip-

ment, which includes high-voltage

bushings. The best option for solving

the tasks of digital substations was

to implement a new type of bushings

with solid insulation like RIN (Resin

Impregnated Nonwoven).

RIN is a resin-impregnated non-

woven synthetic material. This in-

novative in all senses component

allows engineers to create new-

generation high-voltage bushings.

Eliminating paper from solid bush-

ing insulation signifi cantly increases

its moisture resistance. In addition,

requirements for bushings storage

are considerably reduced.

The technology of RIN-insula-

tion manufacturing is almost identi-

cal to the RIP-technology. However,

RIN-insulation properties make it

possible to eliminate long and en-

ergy-intensive operation of thermal

vacuum drying. Besides, the im-

pregnation process leaves no voids

in the insulation material due to the

chemical reaction of synthetic yarn

and epoxy resin. It ensures the ab-

sence of partial discharges inside

the insulation up to the maximum

operating voltage.

The resulting insulation material

has the highest hydrophobic proper-

ties. Due to this, dielectric loss coeffi -

cient is stable and independent from

the eff ects of very high humidity. It

ensures transportability, absence of

special storage requirements, and

reliable operation of the insulation.

Digital substations are designed

to ensure minimal equipment main-

tenance in operation. If something

happens, it is necessary to re-

place failed equipment as easily as

a blown fuse. Bushings with internal

RIN insulation and external polymer

insulation serve these purposes.

When damaging such a bushing,

there are no damages for adjacent

equipment and bushings of adjacent

electrical phases. In this case, it is

enough to replace the bushing for

35

further electric power supply of con-

sumers.

Bushings with RIN insulation are

certifi ed in GOST RF state certifi ca-

tion system. The certifi cates of the

Federal Agency on Technical Regu-

lating and Metrology are obtained.

At present, the certifi cation proce-

dure in PJSC "Rosseti" is at the fi nal

stage.

It should also be noted that RIN

insulation has high thermal conduc-

tivity and a low coeffi cient of thermal

expansion. It helps to decrease volt-

age between mechanically connect-

ed elements of the bushing. This is

important for operation at extreme

temperatures (both high and low).

Also, such properties of RIN insu-

lation open up the possibilities for

creating equipment using supercon-

ductivity phenomenon.

In such equipment, the bushings

must operate reliably at ultra-low

temperatures. At the same time, the

lower part of the bushings should

constantly work in liquid nitrogen at

the temperature of minus 196 °С,

and the upper part — at ambient

temperature.

Conducted studies have shown

that RIN-insulation, using synthetic

nonwoven material, makes it possi-

ble to produce bushings enabled to

withstand all the specifi ed electrical

and mechanical loads in extreme

working conditions (under extreme

temperatures). As a result, Izolyator

plant developed and manufactured

110 and 220 kV bushings, which

passed all acceptance tests. Today,

Izolyator plant is the only manufac-

turer of high-voltage bushings in

the world that has successfully con-

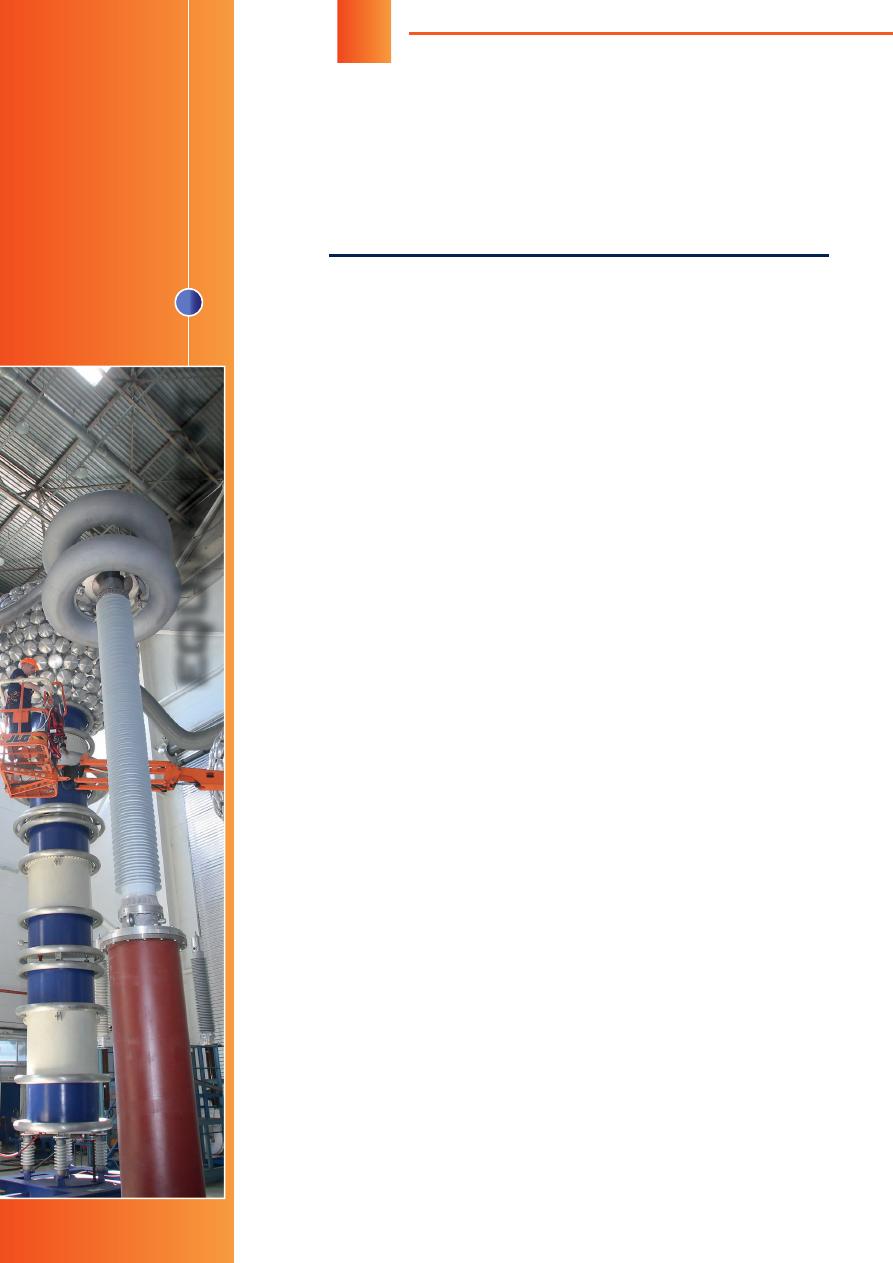

Bushings with RIN insulation in the assembly room of Izolyator plant

New equipment for manufacturing external polymer insulation

of bushings at Izolyator plant

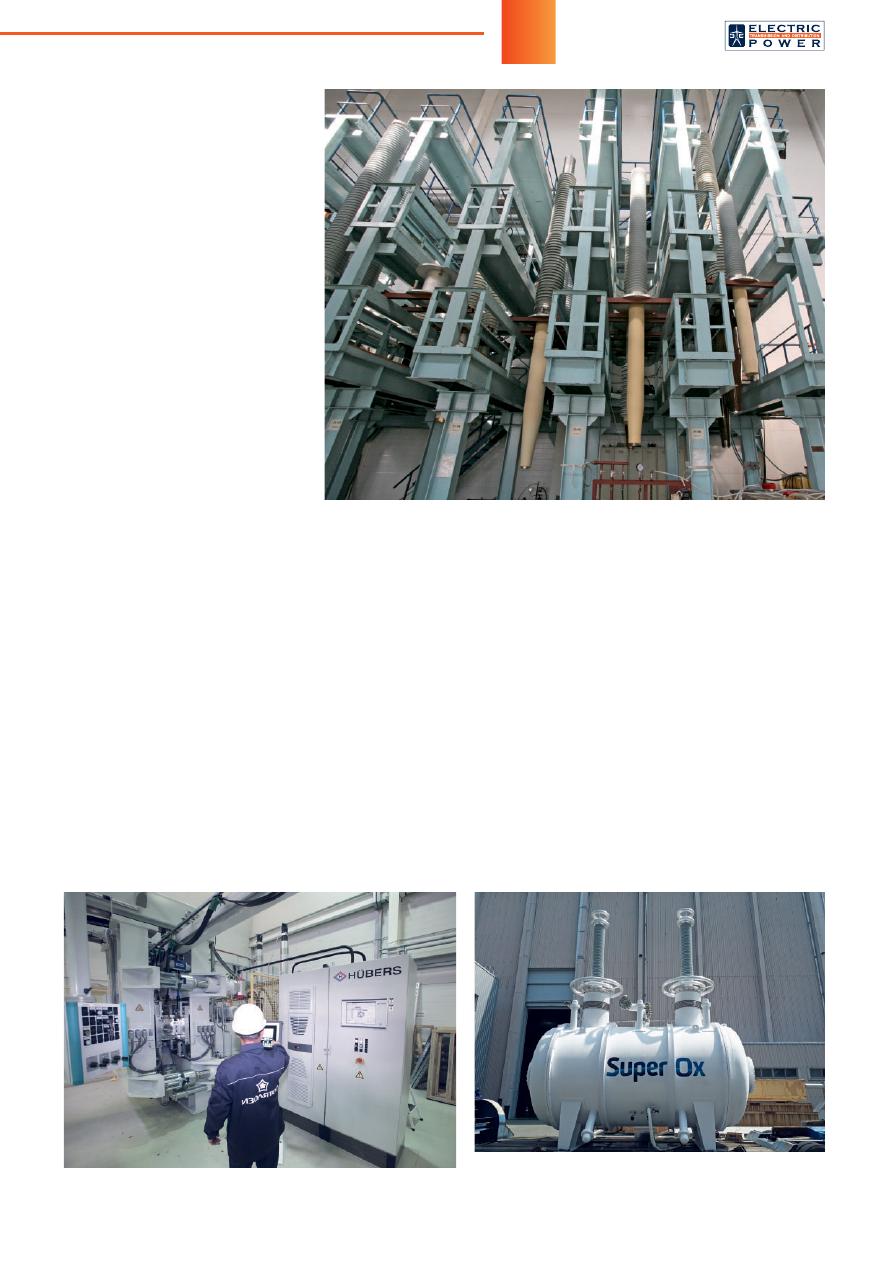

The

fi

rst phase of 220 kV superconducting current limiter,

equipped with bushings produced by Izolyator plant in the

KER test center

ducted acceptance tests of 110 and

220 kV bushings, the lower parts

of which were in liquid nitrogen at

a temperature of minus 196 °С.

Such high-voltage bushings

produced by Izolyator plant proved

their high reliability and quality in

the project of SuperOX company for

creating 220 kV three-phase cur-

rent-limiting device based on high

temperature super conductivity. The

equipment was installed at Moscow

"Mnevniki" substation in 2018. Fol-

lowing the results of the work done,

the company plans to initiate a stan-

dard for the use of cryogenic equip-

ment in power industry.

Foreign orders pose new chal-

lenges to the company, related to

the change of product design, the

search for technical solutions and

non-standard approaches when

manufacturing process. Many new

engineering solutions of Izolyator

plant appear due to foreign orders.

In response to world technologi-

cal challenges and requests from

foreign customers, Izolyator plant

developed and launched into serial

production a line of DC bushings for

long-distance transmission lines. To

the date, complete documentation

has been prepared for the produc-

tion of high-voltage DC bushings.

In addition, plant’s test center has

been equipped with the necessary

equipment. Thus, high-quality do-

mestic bushings for future Russian

The 25th CIRED Session

Special issue, June 2019

36

EQU

I

PME

N

T

long-distance DC transmission lines

already exist.

INTEGRATION

COOPERATION

In the past and present, and well into

the future international cooperation

is an important part of Izolyator Com-

pany operation and development. At

the same time, the company espe-

cially appreciates the opportunity to

prove the reliability and effi ciency

of developed technologies, materi-

als and equipment through one of

the most diffi cult challenges — the

test of time. Due to this, Izolyator

Company constantly opens up new

regions of presence worldwide, es-

tablishing long-term and eff ective

partnership.

In 2018, the company signifi cant-

ly strengthened its relations with

long-standing and reliable partners

from the CIS countries — power grid

companies and energy equipment

manufacturers from Armenia, Mol-

dova, Tajikistan, Kazakhstan, Bela-

rus, Ukraine, Uzbekistan and Geor-

gia. Izolyator Company has found

reliable partners in European and

Asian countries and has contributed

to the strengthening of relations be-

The agreement on joint manufacturing facility establishment between Mehru and

Izolyator was signed during the 47th CIGRE Session in Paris. From left to right:

Andrey Murov, Chairman of the Management Board of "FGC UES", PJSC; I. S. Jha,

Chairman of Power Grid; Sandeep Prakash Sharma, Executive Director of Mehru;

Alexander Slavinsky, Chief Executive O

ffi

cer of Izolyator Plant LLC

Participants of bushing tests for Indian companies TSTRANSCO and TTDI in the test center of Izolyator Plant

tween the national energy systems

of Russia, Vietnam and India.

An important milestone in the

development of the international

relations of Izolyator Company and

entire domestic electrical indus-

try was the signing of a strategic

memorandum with the Indian com-

pany Mehru Electrical & Mechanical

Engineers (P) Ltd on the establish-

ment of a joint manufacturing facility

within the 47th CIGRE Session.

37

Izolyator Company

Leninа str. 77, Pavlovskaya Sloboda,

Istrinskiy District, Moscow Region,

143581 Russian Federation

Tel + 7 (495) 727 3311

Fax + 7 (495) 727 2766

mosizolyator@mosizolyator.ru

www.mosizolyator.com

The signing ceremony of the

Agreement was held at the booth

of Russian National Committee of

CIGRE (RNC CIGRE) in the pres-

ence of Andrey Murov, Chairman

of the Management Board of "FGC

UES", PJSC and Chairman of RNC

CIGRE, and Mr. Jha, Chairman and

Managing Director of Power Grid

Corporation of India Limited and

Chairman of CIGRE Indian NC.

The agreement establishes the

principles of organizing the com-

plete production cycle and further

realization of high-voltage bush-

ings of various voltage classes with

modern solid RIP insulation in India.

The main constructive part, as well

as the know-how of the joint manu-

facturing facility will be the internal

RIP-isolation — Izolyator company

in-house development. It should be

noted that this is the fi rst experience

of Russian companies in creating

a joint manufacturing facility for the

production of high-voltage electric

power equipment with Indian com-

panies.

Mutually benefi cial cooperation

of Izolyator and Mehru will allow the

companies to reduce production and

transport costs and to optimize the

logistics of ultimate product delivery

to the customer. Much attention will

be paid to the maintenance of pro-

ducts both in the processes of its in-

stallation and operation through the

use of developed service and distri-

bution network of the Indian partner.

Izolyator Company plans to con-

duct a full range of high-voltage

bushings tests at the Central Power

Research Institute in India in April

2019.

The type test program includes

a full cycle of electrical, current and

special seismic tests of 420 kV /

3000 A and 800 kV / 2000 A bush-

ings. The most interesting and un-

paralleled anywhere in the world

stage of future international event

will be seismic resistance test of

800 kV / 2000 A bushing.

The main part of the event will in-

clude an open technical conference

for discussing all aspects and tech-

nical features of operation, installa-

tion and maintenance of ultrahigh-

voltage bushings with RIP-insulation

made by Izolyator Company for In-

dian power facilities.

Due to the expansion of interna-

tional cooperation areas, Izolyator

Company has the opportunity to

manufacture products that are com-

petitive not only in the Indian market,

but also in the markets of Southeast

Asia, including China, and in other

regions of the world. In the near-

est future, the company will have

good prospects in the Middle East.

The fi rst steps of cooperation with

Turkey have already been taken. In

addition, cooperation with Syria is

starting and collaborative work with

such a long-time partner as Iran

Transfo company is continuing.

Alexander Slavinsky, D. Sc.,

Chief Executive Offi cer of Izoly-

ator Plant LLC emphasizes that the

company’s staff is always ready to

share unique accumulated experi-

ence with all partners. Sharing of

experience is an integral part of the

mission to create the foundations

for a stable and sustainable energy

supply in the world.

Today, the company sets new

global challenges. For Izolyator

plant it has already become a good

tradition to please consumers with

new materials and technologies

every year. In 2019 the export vol-

ume will be further increased, and

"Made in Russia" brand will be

brought to a new global level.

Р

The 25th CIRED Session

Special issue, June 2019

Оригинал статьи: To Stay Ahead of the Curve, Keeping Adherence to Traditions

For more than 120 years of its history, Izolyator plant has produced more than 620,000 high-voltage bushings, operating in the vast majority of power facilities in Russia and the CIS countries, as well as in 30 countries of the world. Due to active research and development activities, continuous expansion of international relations both in business and in engineering direction, the company is constantly improving its products, offering perfect innovative solutions, which provide the highest level of reliability.