The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

38

diagnosis and monitoring

Th

ermoSensor.

Monitoring of

the State of the Electrical Equipment

Сontact System in 0.4-20 kV Networks

Trends of modern power engineering are focused on digital network development.

One of the tasks of PJSC ROSSETI Concept of Networks Digitalization for 2018-2030

is the implementation of electrical network equipment capable to continuous condi-

tion monitoring and defects identi

fi

cation.

ThermoSensor remote control

system is designed for contact sys-

tem of 6-10 kV Package Outdoor

Switchgear (POS) cubicles, equip-

ment of 6-20 kV Packaged Trans-

former Substations (PTS) and 0.4 kV

switchgears. The system is fully

compatible with PJSC ROSSETI

target technological model of digital

network and provides with possibil-

ity to determine local emergency

overheating of electrical equipment

in continuous mode with subse-

quent automatic signal sending to

the dispatcher console.

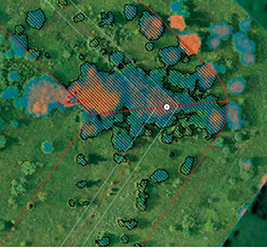

ThermoSensor system (Figure 1)

consists of gas-generating stickers,

a gas sensor and checking and re-

ceiving device (CRD). Stickers are

placed on the contact connections

(CC). When heated, the stickers

change the color and generate sig-

nal gas, which is captured by the

sensor. The overheating signal is

transmitted via CAN bus or Modbus

RTU (RS485) to the CRD, then to

the workstation (WKS), central con-

trol room (CCR), digital communica-

tion center (DCC) and

fi

re alarm sys-

tem. In addition, the sensor beeps.

Also, automatic disconnection of

protected object is possible.

ThermoSensor system provides

fault-

fi

nding before an emergency

shutdown and

fi

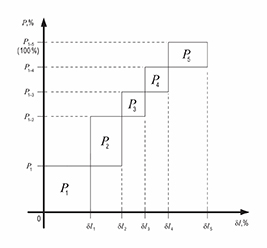

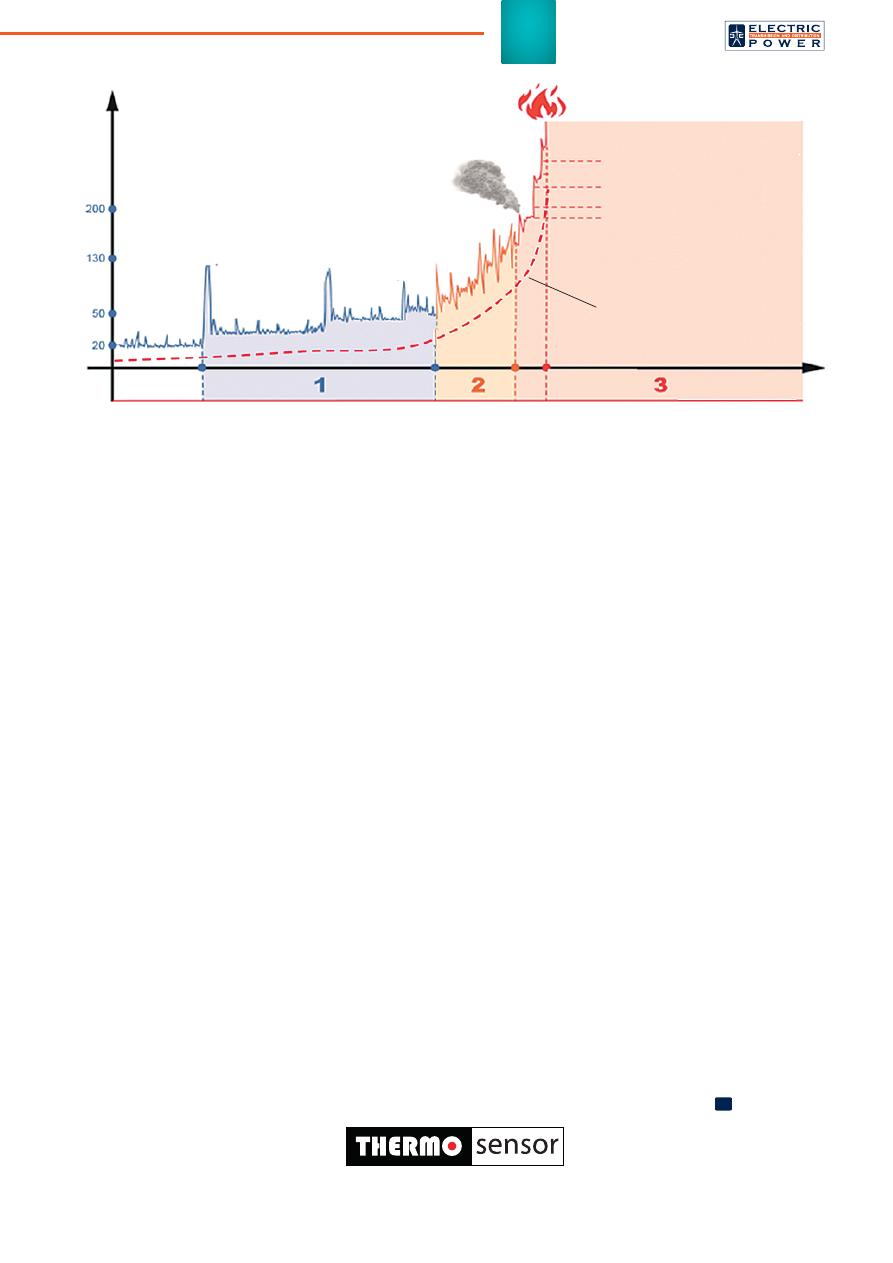

re occur. Figure 2

shows CC heating chronology.

Segment no. 1 on the life cycle line

of electrical equipment demon-

strates time period when CC emer-

gency heating occurs (for example,

as a result of short-circuit currents).

On this segment, planned infrared

control can detect CC heating only

when

fl

owing currents are close

to the maximum. After some time,

the defect grows. Line no. 2 shows

stable CC heating, which is eas-

ily detected by thermal imagers or

pyrometers regardless of the load.

On this segment, signi

fi

cant deg-

radation processes take place in

CC (those processes characterize

CC reliability). During any subse-

quent network disturbance, as well

as long-term day-to-day opera-

tion, this CC can be damaged and

go to the third phase (line no. 3 in

Figure 2). When emergency tem-

peratures are reached, the CC is

destroyed regardless of the load.

When this happens emergency

shutdown occurs and leads to

fi

re

in some cases.

ThermoSensor system auto-

matically

fi

xes single local CC over-

heating up to 80-120º

С

, and trans-

mits a fault signal long before an

emergency or

fi

re occur.

ThermoSensor system advan-

tages in comparison with classic

Figure 1. ThermoSensor innovative system for monitoring of electrical equipment overheating: a) gas-generating

stickers with heat-indicating scale; b) specialized gas sensor; c) checking and receiving device

a)

b)

c)

ThermoElectrika, LLC

Russian Federation,

Moscow, Skolkovo

Innovation Center,

Bolshoy boulevard, 42,

bld. 1, room no. 754,

Tel.: +7 (495) 231-92-99,

info@thermoelectrika.com

www.thermoelectrika.com

Svetlana

VYSOGORETS,

Ph.D., Strategic

Development Director of

ThermoElectrika, LLC

Aleksey LESIV,

Business Development

Director of Thermo-

Electrika, LLC

39

diagnostics of distribution network

electrical equipment are:

• costs saving for expensive ther-

mal imaging;

• inspection personnel drawdown;

• continuous electrical equipment

monitoring without inspection in-

terruptions (including monitoring

during peak loads). It should be

pointed that CC resistance mea-

surement or CC heating control

with pyrometers give a possibi-

lity to assess technical state at

given time under given condi-

tions. With that,

fi

rm prediction

of obsolete electrical equipment

reliability is a systemic scienti

fi

c

and technical problem;

• ability to control nodes which are

not suitable for thermal imaging;

• absence of necessity to discon-

nect electrical equipment for in-

spection purposes. As a result,

there is no need for additional

switching and special modes in

electrical network. It increases di-

agnosis accuracy and ef

fi

ciency;

• ef

fi

ciency upgrade and auto-

matic transmission of data on

detected defect to the customer

or operational personnel and

hence cutting time for remedial

work organization;

• improvement of diagnosing ef-

fi

ciency for electrical equipment

with excess operational life-

time and reducing operational

costs for maintenance. The

frequency of technical diagnos-

tics approved by standards and

technical documentation has

to provide relative reliability of

defects detection in electrical

equipment within its rated life-

time. Defects in worn-out elec-

trical equipment grow much

faster in comparison with equip-

ment working for rated lifetime.

Due to this fact it can be ne-

cessary to shorten the time be-

tween scheduled diagnostics of

obsolete electrical equipment,

to reduce overhaul period and,

as a result, to increase operat-

ing costs;

• ThermoSensor system provides

observability of electrical net-

work, and is a self-diagnosis sys-

tem element for determination

of contact system conditions.

The development of data trans-

fer system from ThermoSensor

CRD to utility’s network manage-

ment system gives a possibility

to provide intellectual adapta-

tion of network operation modes

depending on network technical

conditions (as an example of

such adaptation is interdiction to

connect load to cubicles where

emergency overheating is de-

tected);

• integration of the ThermoSensor

system in post-accident monitor-

ing system (PAMS) improves ac-

curacy of real technical condition

index calculation. The improve-

ment of the system for collecting

and analyzing ThermoSensor

operation results gives a chance

to evaluate repair work ef

fi

cien-

cy. Among the estimated factors

are materials and technologies

used, the quality of repair crews

operation, and distribution net-

work elements deterioration.

Thus, the ThermoSensor sys-

tem provides effective control of

equipment reliability taking into ac-

count the revealed shortcomings

of the classical diagnostic system.

The technical result of the Thermo-

Sensor system implementation is

a reduction of emergencies in elec-

trical networks and an increase of

operation ef

fi

ciency.

Experimental operation of the

ThermoSensor system and its im-

plementation as a pilot project are

already conducted at a number of

major Russian enterprises. Ther-

moSensor system ef

fi

ciency was

proved by full-scale tests carried out

at the facilities of PJSC "MOESK",

LLC "ABB" (tests in 6-25 kV switch-

gear cubicles) and JSC "UNECO"

(tests in RM6 cubicles).

ThermoSensor system produc-

tion is located in the Russian Fede-

ration. It is protected by patents

and has the necessary certi

fi

ca-

tion, including certi

fi

cate of FGBU

VNIIPO of EMERCOM of Russia.

The ThermoSensor system is the

cheapest technology in the world,

characterized by simple installation

and maintenance.

Р

Figure 2. Heating chronology of contact connection (CC)

CC temperature, °

С

Ignition

Life cycle

Existing solutions:

The line of CC thermal

defect development during

the life cycle

Thermal indicators

Smoke indicators

Aspirating systems

Gas detectors

ThermoSensor system is a Russian

innovative solution for gas analytical

control of CC heating of distribution

network electrical equipment. The system has competitive advantages in

comparison with technologies for CC overheating detection and has no ana-

logues in the world.

47th CIGRE Session

Special issue, August 2018

Оригинал статьи: ThermoSensor. Monitoring of the State of the Electrical Equipment Сontact System in 0.4-20 kV Networks

Trends of modern power engineering are focused on digital network development. One of the tasks of PJSC ROSSETI Concept of Networks Digitalization for 2018-2030 is the implementation of electrical network equipment capable to continuous condition monitoring and defects identification.