45

THE FAR EAST

BECOMES CLOSER

The point of departure for the

Far East power engineering in-

dustry development was the year

of 1912, when the

fi

rst CHP was

constructed in Vladivostok. Geo-

graphic features of the region,

such as signi

fi

cant environmen-

tal assets and its deployment dif-

fi

culties, isolated from the center

of Russia location and proxi mity

to the ocean coast, huge terri-

tory and low population density,

have de

fi

ned the further economic

development of the region and

its power engineering industry.

Probably none of the Russian

regions hasn`t developed in the

same hard and bendy way, as the

Far East, occupying 36% of the

country territory.

Large Bureyskaya and Zey-

skaya HPP with the total capacity

of 3.3 GW, Khabarovskaya CHP-1

and CHP-3 with the capacity of

over 1.1 GW, Neryungrinskaya

SDPP are situated near the hund-

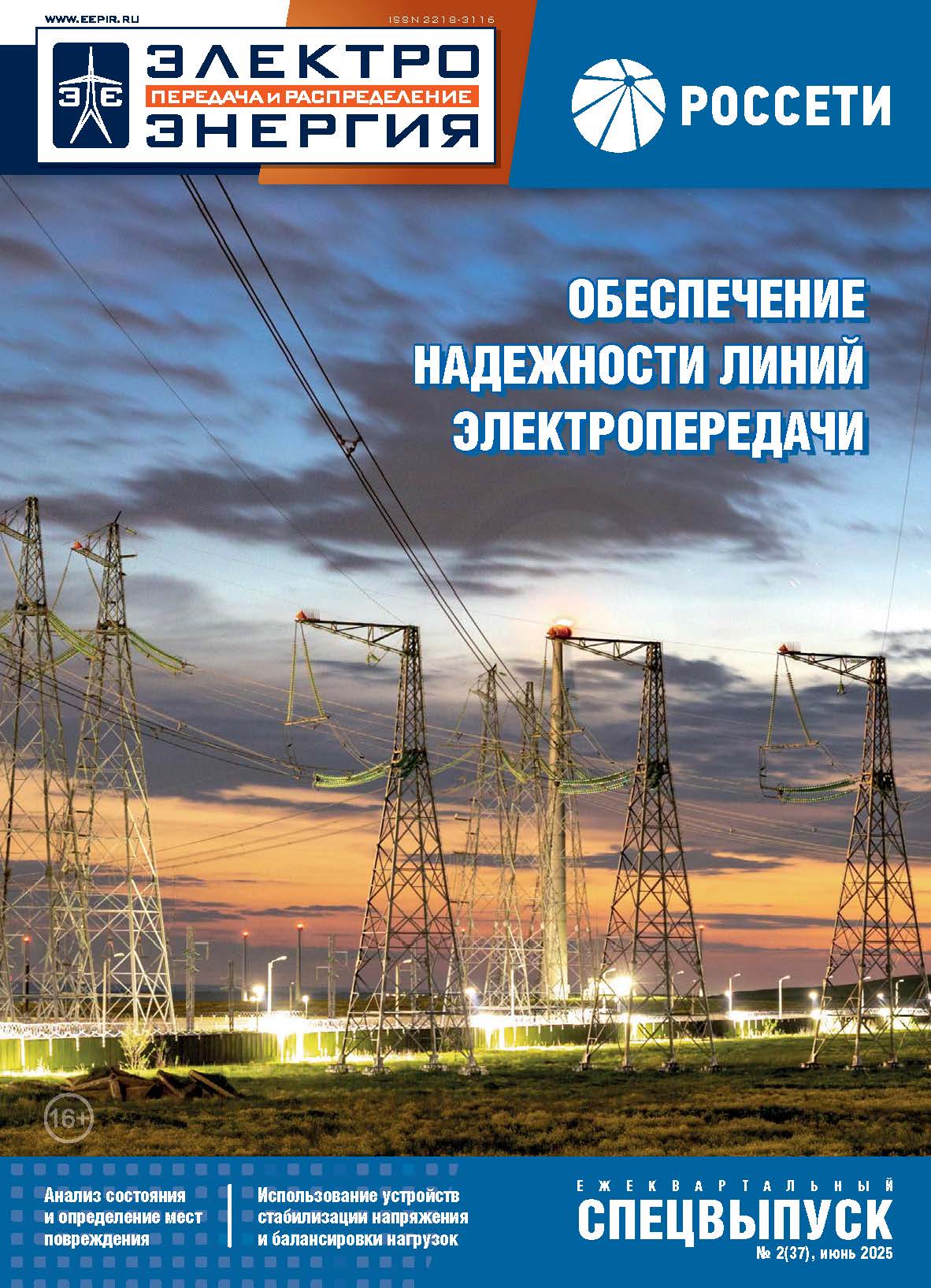

Powerhouse hall of the Far East largest

Bureyskaya HPP

fi

tted with

“Power Machines” equipment

Technologies

“Power Machines” company takes part in the works on the three of four heat

generation units erected within the federal program of economic and social

development of the Far East and Transbaikal: this is Blagoveshchenskaya CHP

2nd construction stage, Yakutskaya SDPP-2 1st construction stage and also the

CHP in the city of Sovetskaya Gavan. In addition, the company takes part in the

large hydropower project of the region – Nizhne-Bureyskaya HPP construction.

The Special Region

46

reds of DP supplying one or two

small villages. Also dozens of

units, similar to Mayskaya SDPP

in Sovetskaya Gavan, Artemovs-

kaya CHP and Komsomolskaya

CHP-1 are situated there. Men-

tioned plants were put into opera-

tion already in 1930s and have

been overaged at the moment.

All four projects are aimed to

the signi

fi

cant alterations of the

power engineering situation in the

region starting with the amount of

the generated power and

fi

nishing

with its cost and operating plants

ecological cleanness.

As for today the potential of

enterprises forming part of “Power

Machines” allows to meet cus-

tomer requirements in almost all

the types of power plant equipment

starting with turbines and

fi

nish-

ing with boilers and trans

-

formers.

Red Alert

Two steam turbines with the

regulating cogeneration steam

tapping with the capacity of

63 MW each were delivered to

the CHP in Sovetskaya Gavan

by OJSC “Kaluga Turbine Works”

in 2015. According to the Chief

Structural Engineer of OJSC

“Kaluga Turbine Works” Leonid

Muzarev opinion, the equipment

was designed especially for the

mentioned unit: “Special feature

of the turbines produced for the

“Sovetskaya Gavan” CHP is main

steam high pressure which is

13 MPa. The turbine is single-unit

and the rotor is solid-forged”.

Taganrog boilermaker “Krasny

Kotelshchik” became one more

“Power Machines” enterprise,

which takes part in the works for

Sovetskaya Gavan. It produced

three new boilers for the CHP

electrical power units. Every boiler

steam-production capacity is

210 tons of steam per hour. For

its construction staged scheme of

fuel burning was implemented. It

allows to increase environmental

measures of equipment by oxygen

level and

fl

ame body temperature

decrease. At the moment the

boilers, produced for Sovet-

skaya Gavan in Taganrog, as the

turbines of OJSC “Kaluga Turbine

Works”, have been delivered to

the plant.

In the Perma-

Frost Zone

Also “Power Machines” takes

active part in the production of

equipment for the Yakutskaya

SDPP-2. The new plant will

replace the retired capacities

of the operating SDPP, which

provides 94% of the electrical

energy consumption of the Sakha

Republic (Yakutia) nine districts

and 54% of its capital – Yakutsk

heat consumption. Rated electrical

capacity of the new Yakutskaya

SDPP-2 will be 193 MW, heat

capacity – 469 Gcal/h.

Yakutskaya SDPP-2 speci

fi

c

characteristic is its location in the

permafrost zone, which assumes

a number of design features both

for the plant building and for the

equipment applied at it. So, the

base plate of the plant building

in the permafrost conditions is

established on piles at the height

of three meters over the earth.

At the same time temperature

around Yakutsk falls up to –64°C

in winter. Units that are similar to

the plant in region have not been

built in the region since 80s, so

in the new project a number of

modern technical solutions have

been applied for the

fi

rst time.

“Waste-heat recovery units

designed for the Yakutskaya

SDPP-2 possess high stability to

the thermal shocks and low heat

retention. This feature will allow the

equipment putting into operation

in short terms, design engineer of

Taganrog design center Alexander

Kolesnikov says. – In addition,

the possibility of trouble-free

operation at seismic in

fl

uence by

intensity to 7 points is involved in

the boilers of that modi

fi

cation.

Lack of the developed transport

infrastructure around Yakutskaya

SDPP-2 was also estimated at the

design stage. This condition has

in

fl

uenced on mass-dimensional

parameters and separate units

design signi

fi

cantly”.

General Contract

In the project of the Blago vesh-

chen skaya CHP 2nd construc-

tion stage “Power Machines” is

a gene ral contractor. After the 2nd

con struction stage ful

fi

llment the

plant installed electrical capacity

was 400 MW, heat capacity was

1005 Gcal/h.

Blagoveshchenskaya CHP is

the newest in the Far East quad-

ruple. Its 1st construction stage

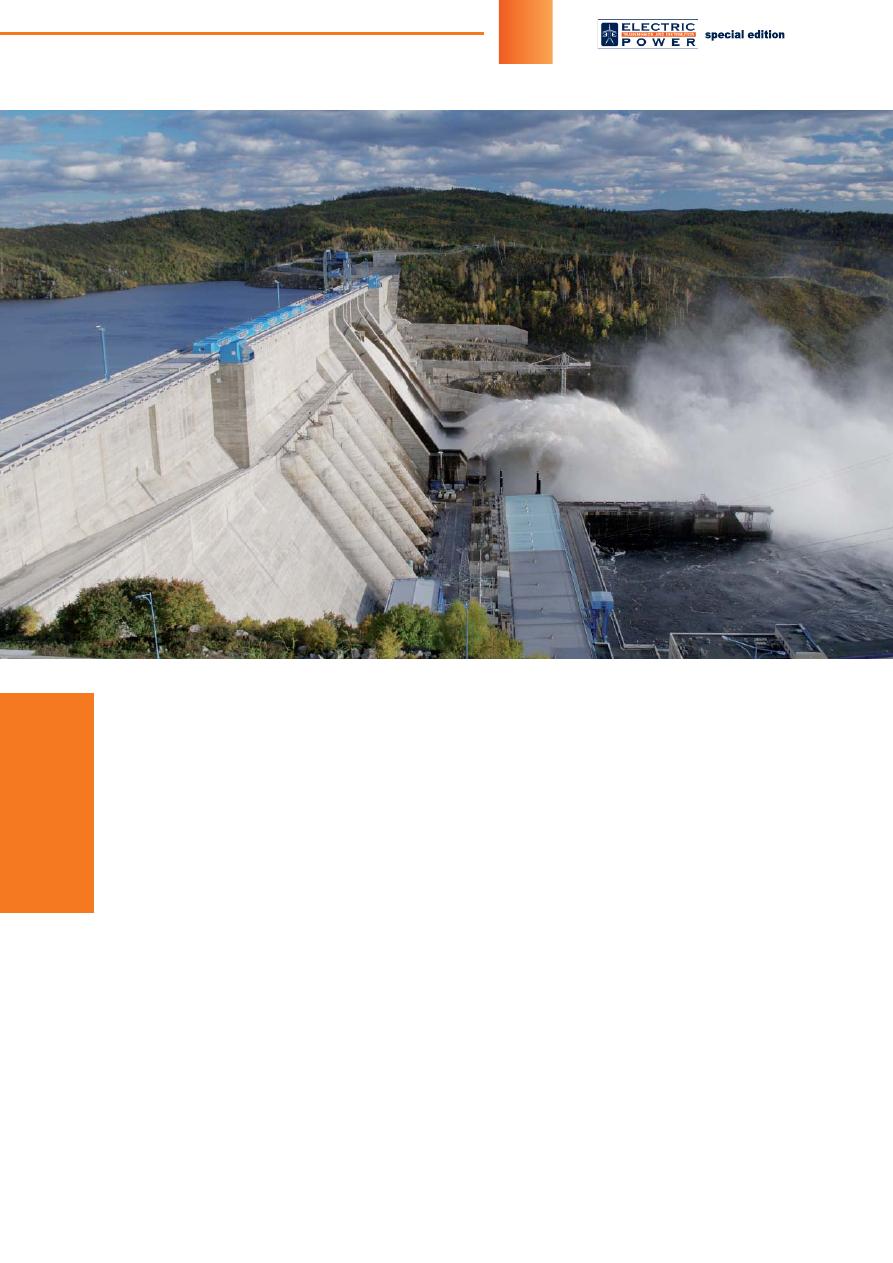

Unique unit – Yakutskaya SDPP-2 – is constructed

under severe conditions of permafrost

47

was put into operation completely

in 1985. CHP project includes also

the 2nd construction stage, but the

construction was interrupted be-

cause of economy problems in the

middle of 90s. As a result the lack

of capacity has led to the freeze

of engineering speci

fi

cations out-

putting for new connections to the

networks from the part of the plant.

Also the reserve of heat capacity

in boiler rooms which provide heat

power to the housing stock was

depleted. For the actively deve-

loping Blagoveshchensk it meant

a suspension of many plans, so

the CHP inclusion in the list of the

most priority objects of the region

is more than justi

fi

ed.

The contract signed between

“Power Machines” and CJSC

“Blagoveshchenskaya CHP”, “Rus -

Hydro” absolute af

fi

liated depen-

dent society, included implemen-

tation of installation and mounting

works within the reconstruction

of the earlier preserved site area,

production and delivery of all ne-

cessary equipment for the opera-

tion. The list of equipment included

a steam turbine with the capacity

of 120 MW completed with tur-

bine-type alternative, gene

rating

unit with excitation system, PC-

fi

red steam boiler and power and

unit transformers with the capacity

of 160 and 25 MVA.

The First Stage of

the Large-Scale

Construction

On the eve of 2016 “Power

Machines” has

fi

nished the 1st

stage of the Blagoveshchenskaya

CHP 2nd construction stage. The

new stage was put into opera-

tion. “Power Machines” realized

that owing to the consolidation of

the company`s diversi

fi

ed compe-

tences.

All involved divisions and plat-

forms functioning was coordi-

nated within the single integrated

activity-based network. According

to the project manager Vladimir

Mirzak, not only the short terms

of construction were the feature

of the project. “Much work had

to be carried out just-in-time, and

we managed to sign contracts, to

purchase the equipment and to

start implementation during the

time which usually only the study-

ing of documentation takes. In

conditions when the track of time

was estimated in hours, accurate

performance of technical proce-

dures became especially impor-

tant. Implementation of the SAP

system and also the Oracle Pri-

mavera program in the company

became not the last factor which

has de

fi

ned the project success,

due to the capability of mentioned

programs to increase projects

management to the level of the

international standards”, Vladimir

Mirzak tells.

Feature of the project also con-

sisted of the fact that its realiza-

tion was carried out on the site

area of the already operating plant

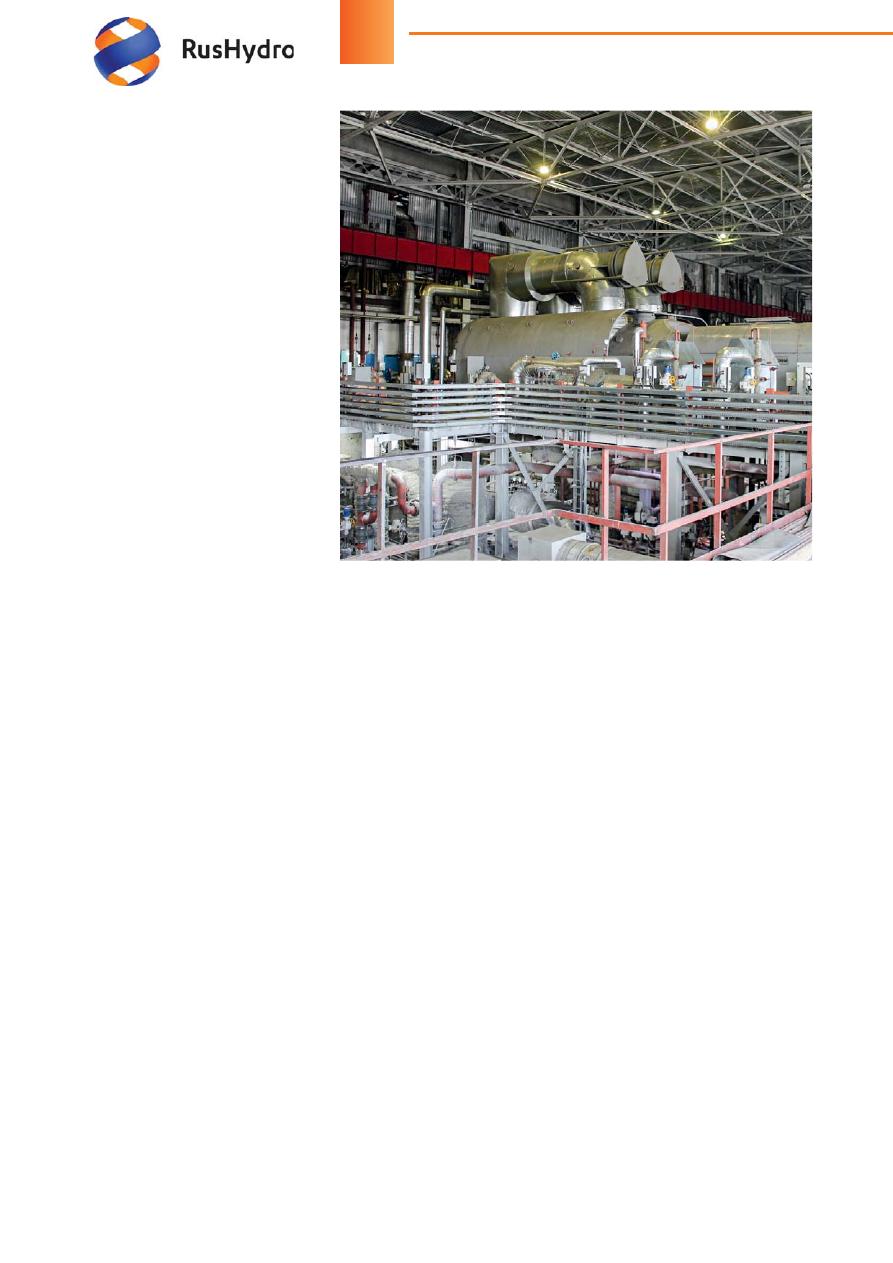

Transformers for the Blagoveshchenskaya CHP 2nd construction stage were

produced at the Power Machines Toshiba High-Voltage Transformers LLC

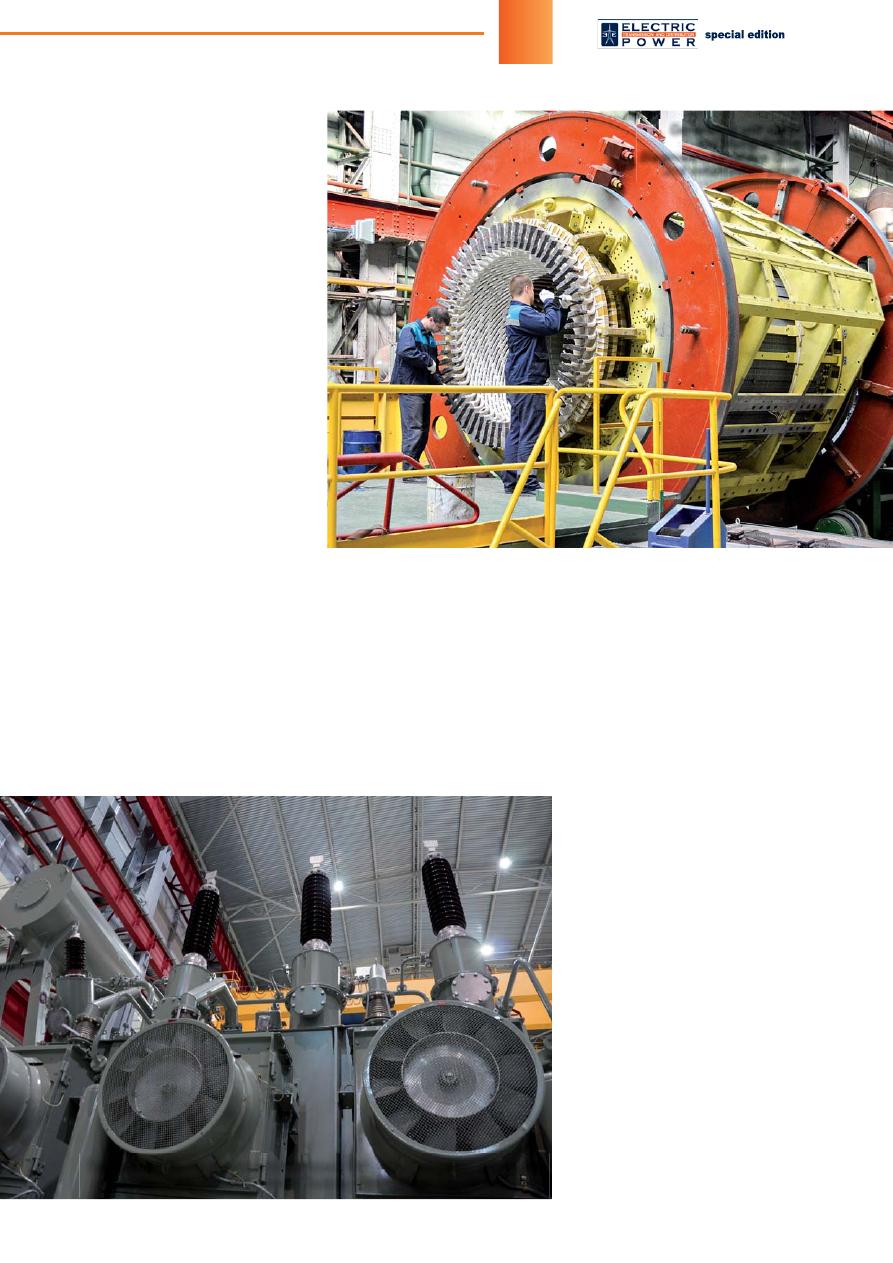

Generating unit stator

coil laying for the

Blagoveshchenskaya CHP

2nd construction stage

48

Power house of Blagoveshchenskaya CHP

2nd construction stage

1st construction stage. Besides

not all the units were under con-

struction from the green

fi

eld: the

part of the construction designs

built in the late 80s – the early 90s

was reconstructed and built-in to

new buildings. “To

fi

t the size of

the previous model machine, plant

designers have improved the cool-

ing system of the new turbine-type

alternative for the Blagoveshchen-

skaya CHP. Another fan, another

distributor of the stator coil cool-

ing system have been installed. In

addition, isolation with increased

thermal conduction was imple-

mented in the machine”, turbine-

type alternative Chief Structural

Engineer of “Power Machines”

Oleg Antonyuk says.

Everything

Is Own

Availability of own production

at “Power Machines” became one

more important component of the

project. After the signing of the

contract work on its implementation

has begun in parallel at a site

area in Blagoveshchensk and at

production site: in St. Petersburg

and Taganrog.

Speaking about the equipment

technical features, we should pay

special attention to the turbine-

type alternative, designed and

produced owing to “Elektrosila”

works, and also a boiler, designed

by the specialists of the Barnaul

branch of Taganrog “Krasny

Kotelshchik” boilermaker.

According to the contract re-

quirements, a new much more

heavier generator was necessary

to be combined with the param-

eters of the buildings constructed

in 1980s. Structural alteration of

the machine cooling system as-

sisted to achieve the necessary

result. That alteration allowed to

use air instead of hydrogen, and

also to implement stator coil with

the usage of insulating materials

with the increased parameters of

thermal conduction. As a result,

turbine-type alternative with inte-

grated water cooling of stator, ro-

tor and the core with the capacity

of 130 MW could save the model

size of turbine-type alternative

with hydrogen forced cooling and

the capacity of 110 MW obtaining

20 MW of additional capacity.

As for the boiler, the require-

ments of ecological safety

meeting became one of the

major tasks at its production.

Low-issue burners and fuel con-

sumption staged system have

been applied for the emission

of nitrogen oxides decrease.

Up to 98% of exit-gas ash can

be collected now by the con-

temporary electro

fi

lters, and slag

is directed through the bottom

ash-handling system to the

water channel and to storing.

Thus, a new electrical power unit

with the capacity of more than

120 MW and 188 Gcal/h putting

into operation practically hasn’t

increased an environmental

pressure on the city.

For ecological and techno-

logical safety the new electrical

power unit in Blago veshchensk is

equipped with automatic control

system, capable to con

fi

gure work

settings independently.

At the moment the new elec-

trical power unit has success fully

passed certi

fi

cation and guarantee

tests. 200 hours of tests of boiler

unit number 5 and boiler unit

number 4 proved the equipment is

managed to operate satisfactorily.

Till October, 2016 the

fi

nishing

work will be continued at the plant:

fuel feeder is updating, ancillary

facility is at the

fi

nal construction

stage, and provision of amenities

is carried out. In 2 years ahead

“Power Machines” has to ful

fi

ll

warranty obligations, including

advising personnel of the plant on

the questions connected with its

operation.

Against

the Nature

The largest waterways –

Zeya, Amur and Bureya rivers

of the region have always been

a great resource for the Far East

power engineering industry. So

that Ust-Srednekanskaya HPP in

the Magadan region and Nizhne-

Bureyskaya HPP in the Amur River

region construction works are going

on. Equipment for mentioned plans

will be delivered also by “Power

Machines”.

Nizhne-Bureyskaya HPP will

become not just the heaviest

49

power generator for the region,

but also will undertake a mission

on

fl

oods

prevention.

The

plant will be so-called counter-

regulator for Bureyskaya HPP,

in which construction, by the

way, in due time the “Power

Machines” enterprises also took

part. Among its functionalities

the equalization of Bureyskaya

HPP discharges during the day

and also settlement waterlogging

prevention will be.

Nizhne-Bureyskaya HPP esti-

mated capacity will be 320 MW,

annual average generation will

be 1650 million kWh. The agree-

ment on the delivery of four

hydro electric installations with

the capacity of 80 MW each for

the Nizhne-Bureyskaya HPP was

signed in the end of 2013, put-

ting it into operation is planned

till the end of 2016. Ecologically

safe design of hydroturbines is

among distinctive features of

the project: six meters impel-

ler cavity, where the mecha-

nism of runner-vane opening is

located, won’t be

fi

lled with oil.

That excludes a possibility of its

leakages in water. “On produc-

tion of such components – eco-

logically safe impellers large

in size – “Power Machines” is

second to none,” head of design

engineering sector of radial-

axial hydroturbines companies

Alexey Roganov says. “Modern

steam path with a new bucket

wheel system will also become

the important feature of the

Nizhne-Burey skaya HPP aggre-

gates. This will allow providing

as great as practicable ef

fi

ciency

factor”.

According to the agreement

con ditions “Power Machines” will

design, produce and deliver four

equipment package of hydro-

electric installation to the custo-

mer. Each of them includes Kap-

lan hydroturbine completed with

a system of automatic con

trol,

water-wheel generator com-

pleted with excitation system and

ancillary equipment of hydro-

electric installation as well.

Equipment production for

Nizhne-Bureyskaya HPP

PJSC “Power Machines”

3A Vatutina St.,

St. Petersburg, 195009, Russia

+7 (812) 346 70 37

www.power-m.ru

Оригинал статьи: The Far East Becomes Closer

“Power Machines” company takes part in the works on the three of four heat generation units erected within the federal program of economic and social development of the Far East and Transbaikal: this is Blagoveshchenskaya CHP 2nd construction stage, Yakutskaya SDPP-2 1st construction stage and also the CHP in the city of Sovetskaya Gavan. In addition, the company takes part in the large hydropower project of the region – Nizhne-Bureyskaya HPP construction.