The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

30

August 25–29, France, Paris

Grid Control

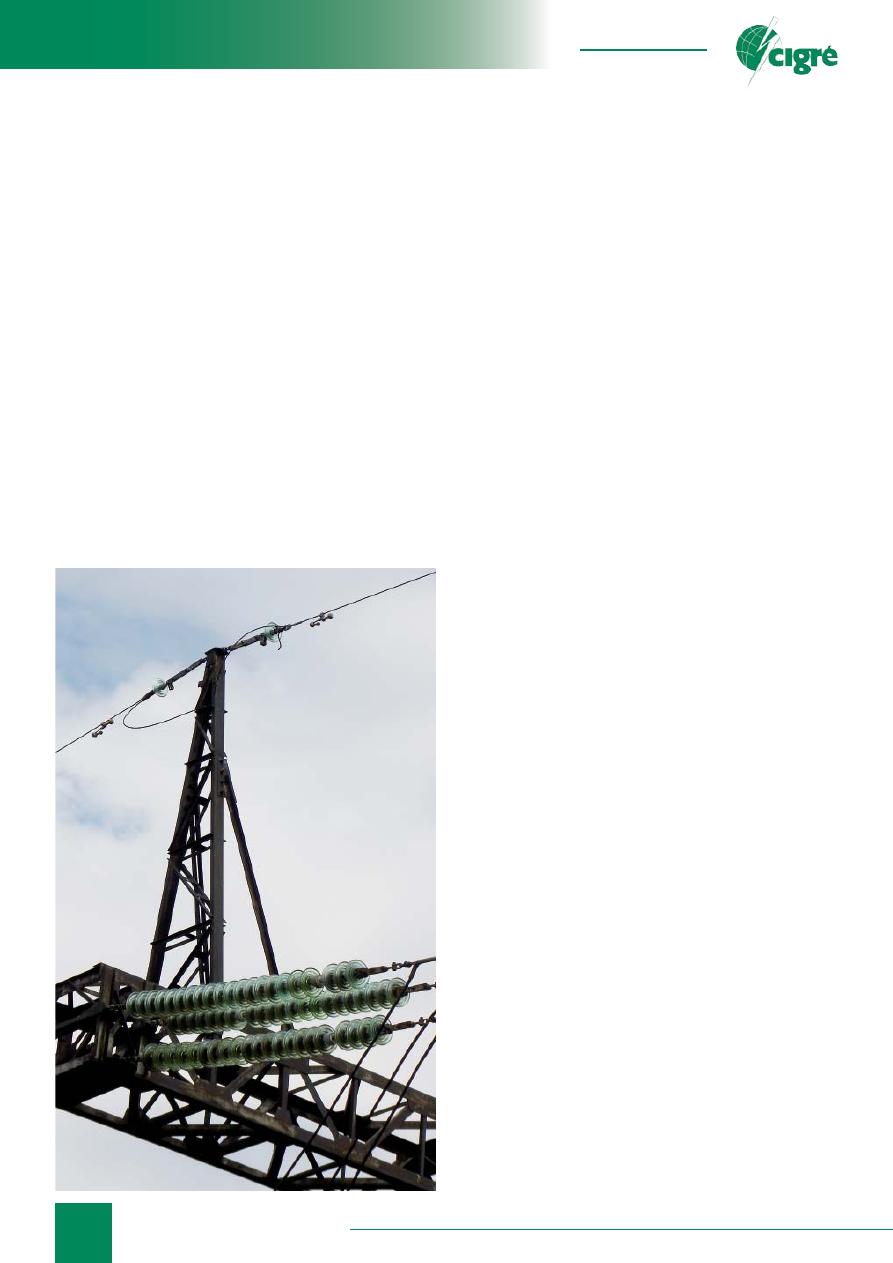

A

long with the standard information

fi

ber-

optic cables (FOC), made with dielectric self

supporting cables, overhead ground-wire

cables made of steel wires with different

coatings containing stainless steel module which

comprises optical

fi

bers in hydrophobic semi-liquid gel

are widely used (OPGW). This design provides necessary

mechanical strength and is a product of dual purpose: it

performs the traditional role of protecting power lines

from lightning strikes and used as communication and

data transfer cable.

OPGW must satisfy JSC FGC UES traditional

requirements to overhead ground-wire cables: mechanical

strength, corrosion resistance, resistance to lightning

discharges, Aeolian vibrations, Galloping, as well as short

circuit withstand capability.

Steel wire used in OPGW layers must be protected

against corrosion, therefore zinc or aluminum coatings,

signi

fi

cantly more resistant to oxidation than steel core,

are used. Resistance to corrosion and speci

fi

c conductivity

of aluminum coating is slightly higher than zinc, however,

such coatings have a number of disadvantages. Outdoor

contact of stainless steel and aluminum causes active

corrosion: atmospheric salt and chemical contaminations

on the surface of the metal act as the electrolyte and lead

to accelerated destruction of aluminum. Therefore the

international standard IEEE-1138-2009 for zones with

high corrosive activity, which include all industrial and

Temperature and Current

Density Simulation in Overhead

GroundWire Cable with Fiber

Cable (OPGW) under Short

Circuit Current Passage

Leonid GUREVICH (

Леонид

ГУРЕВИЧ

),

Vladimir DANENKO (

Владимир

ДАНЕНКО

),

Dmitry Pronichev (

Дмитрий

ПРОНИЧЕВ

),

М

ikhail TRUNOV (M

ихаил

ТРУНОВ

),

Volgograd State Technical University

31

info@eepr.ru, www.eepr.ru

densely populated areas, prohibits the usage of OPGW

optical module made of stainless steel and aluminum

coated wires.

Moreover, the comparative tests to withstand lightning

charge up to 110 coulomb carried out on “Four-part

lightning current generator” (GTM-4) test bench in

Moscow Power Engineering Institute under the same

tension revealed that shield wire made of aluminum-clad

steel wire suffered the greatest damage.

OPGW usage requires to calculate thermal resistance,

provided that not only residual mechanical strength of

the cable, but also effective heat removal from the optical

module are considered. Regulations for design of

fi

ber-

optic communication lines on OHL

require thermal stability analysis of

optical cable when subjected to fault

currents.

OPGW thermal withstand analysis

included the following calculations:

• dynamic magnetic

fi

eld caused

by the AC pulse frequency of 50

Hz and a duration of up to 1 s in

order to obtain the current density

distribution in each of the cable

conductors, depending on the time;

• unsteady temperature

fi

eld using

Joule losses as the heat source.

The simulation used Magnetic

Fields and Heat Transfer in Solids

modules license software package

COMSOL Multiphysics, capable of

solving partial differential equations.

For simulation diagram of ground

wire with grade OPGW 11,0/

Е

1(12)-

MZ (ground wire with diameter

11.0 mm with built-in optical

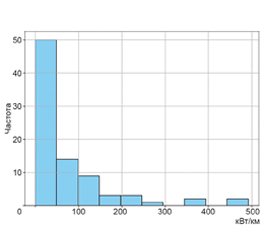

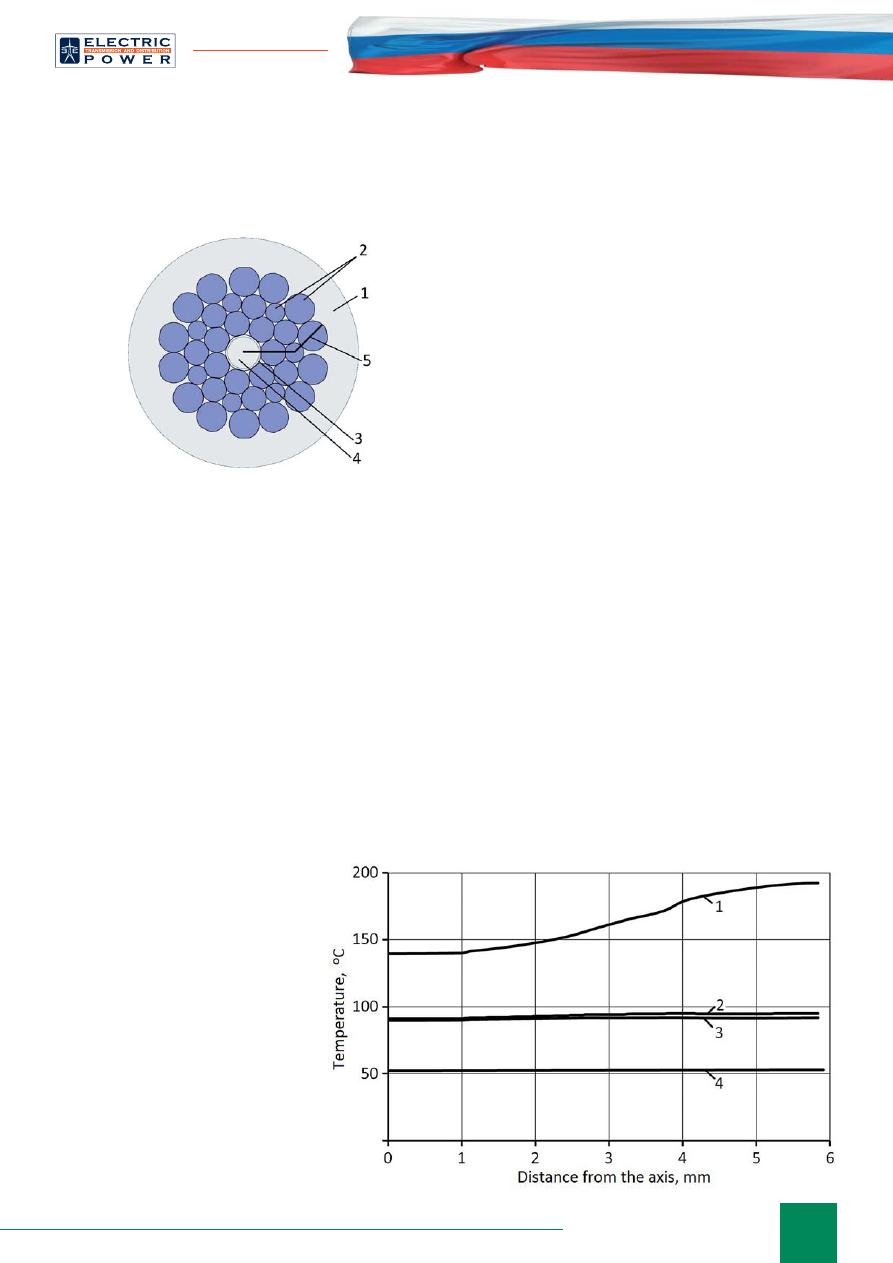

Fig. 1. OPGW thermal withstand capability

design diagram: 1 — air; 2 — steel wire;

3 — central tube; 4 — optical

fi

bers in

hydrophobic gel; 5 — the line along which data is

presented in Fig. 2.

Fig. 2. Temperature distribution in OPGW along the line shown in

Fig. 1 at

J

fc

= 4.3 kA current through 1 s:

1 — uncoated steel wires, 2 — zinc coating, 3 and 4 — aluminum

coating, thickness 20 and 260

μ

m

communication cable) made according to the technical

conditions enterprise standard 71915393-TU 113-2013

(Fig. 1) was used.

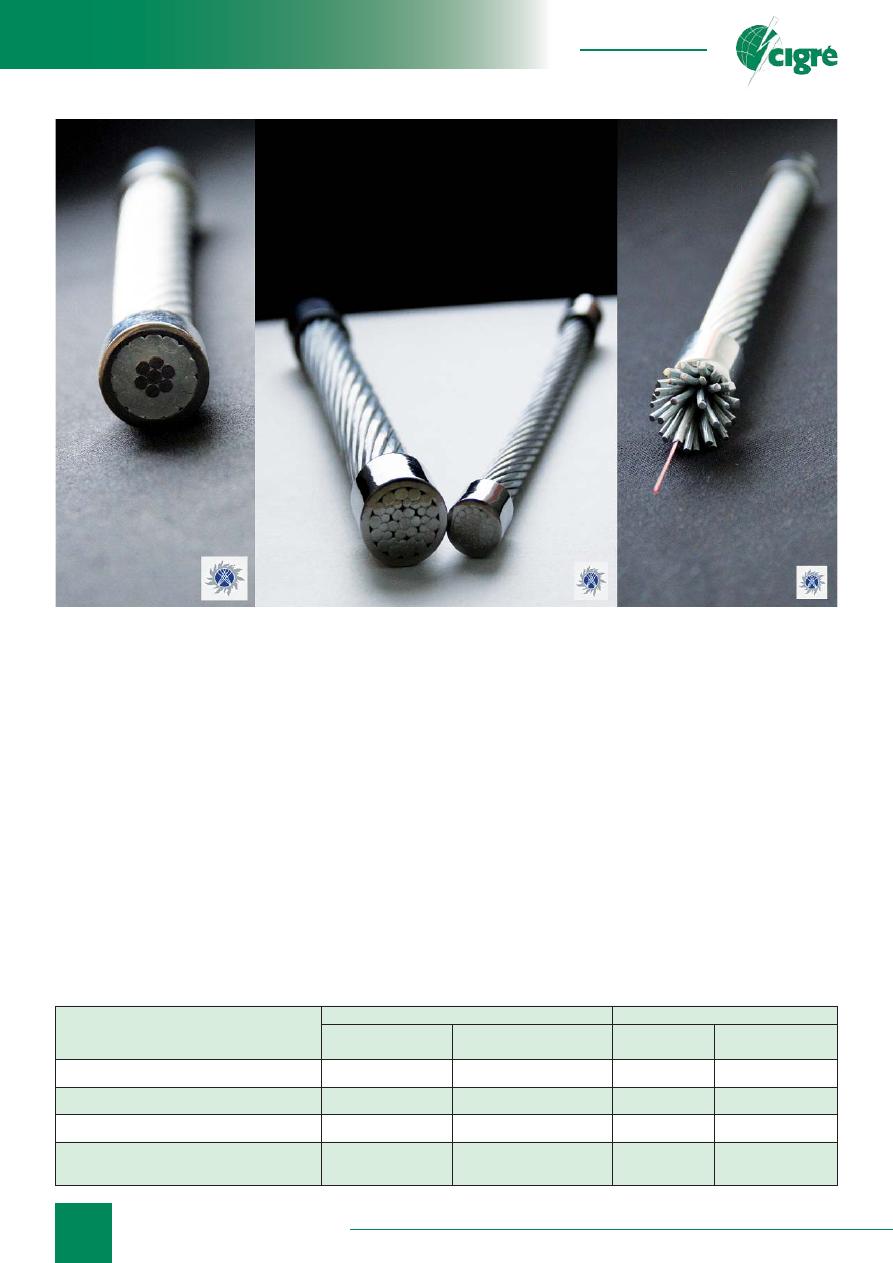

While thermal analysis four possible variants of steel

wire surface coating were compared:

• steel rods with zinc coating for particularly harsh

environment operation (corresponds to OPGW really

made by Severstal-Metiz JAC according to enterprise

standard 71915393-TU 113-2013);

• steel rods without coating;

• steel rods with aluminium coating which thickness

corresponds to zin

с

coating of

fi

rst variant (20

μ

m);

• steel rods with aluminium coating with volume

aluminium content up to 25%.

The simulation results were veri

fi

ed by experimental

data of

fi

eld tests in OPGW high voltage equipment test

center of JSC NTC FGC UES showing that 1 second

passage of 4.3 kA short circuit current increased cable

temperature by an average of 88°C.

It was found that current density in uncoated steel wire

increases with distance from the axis of the cable, which

leads to substantial increase in temperature in the outer

wire layers (Fig. 2).

The use of zinc or aluminum coating results in

predominant current

fl

ow in them (current density in these

coatings respectively is 4 and 9 times the current density

in the carbon steel core). The difference in current density

in external and internal layers is not signi

fi

cant. Under 1

second fault current

J

fc

= 4.3 kA the use of coating zinc

reduced the temperature in optical module area by 35°

C and in the outer layer — by 83° C. The use of 20

μ

m

aluminum coating with increased electrical conductivity

allows to further reduce the temperature in the optical

32

August 25–29, France, Paris

Grid Control

module by 15° C, however, in the case of both zinc and

aluminum coatings temperatures lie in the safe range and

do not lead to degradation of optical properties of optical

fi

ber. During simulation the increase of aluminum coating

thicknesses to 25% volumetric content provided under

selected current value of

J

fc

= 4.3 kA temperature increase

only up to 52°C. This aluminum content is too high with

respect to temperature stability at current

J

fc

= 4.3 kA and

is appropriate only at

J

fc

= 6.2—6.3 kA currents.

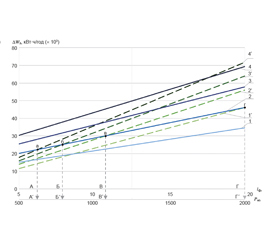

Speci

fi

c resistance/cable coating dependence is often

not analyzed in choosing OPGW wire coating material.

For OPGW under consideration when using uncoated

steel wires DC resistance value

R

= 3.1 ohm/km, with

zinc coating

R

= 2.2 ohm/km, with 20

μ

m thick aluminum

coating

R

= 1.9 ohm/km.

Shield wire DC resistance reduction when replacing zinc

coating for aluminum will inevitably lead to an increase

in forced and active components of fault current that can

neutralize determined by laboratory testing and modeling

the lower values of temperature

fi

elds in ground steel wires

with aluminum coating over wires with zinc coating.

Change in strength characteristics and critical de

fl

ection

for OPGW made by Volgograd Af

fi

liate of Severstal-

Metiz when replacing steel galvanized rod of 1770 MPa

marking group with steel aluminized one with aluminium

volume content 25% was evaluated. Cross-sectional area

of all wires in OPGW of existing construction is 83.59

mm

2

, approximate weight of 1000 m lubricated ground

cable is 695 kg and actual aggregate breaking strength is

at least 147 kN. OPGW coating changed, the weight is

reduced to 515 kg. Aluminum-coated steel wire tensile

strength

σ

bim

calculated according to the additivity concept

is 1342 MPa and actual aggregate breaking strength of all

wires is less than 112 kN.

Table 1. Calculation of linear and speci

fi

c loads in OPGW under its own weight, the weight

of ice and wind pressure

Load Designation

OPGW with Galvanized Rods

OPGW with Aluminized Rods

Linear Load, N/m

Speci

fi

c Load, MPa/m

Linear Load,

N/m

Speci

fi

c Load,

MPa/m

from proper weight

6.82

0.0815

5.05

0.0604

from glaze ice weight

19.11

—

19.11

—

from wind pressure while glaze ice

24.72

—

24.72

—

resultant from proper weight, glaze ice

weight and wind pressure while glaze ice

40.22

0.6415

39.11

0.6238

33

info@eepr.ru, www.eepr.ru

When using OPGW in Russian area of the third groups

by wind pressure (1 time per 25 years wind pressure up to

0.67 kPa) and by glaze ice (1 time per 25 years standard

thickness of glaze ice layer up to 20 mm) calculation

according to EIC-7 results in the following values of

linear and speci

fi

c loads (Table 1).

With a span length of

l

=300 m minimum allowable

sag under the action of wind and ice loads at permissible

stresses in ground wire equal to 50% of ultimate tensile

strength of the wire being used is 8.15 m for OPGW

of galvanized steel wires and 10.46 m for OPGW of

aluminum-coated steel wire.

Thus, the use of aluminized wire with high aluminium

content in OPGW manufacture leads to considerable

reduce in bearing capacity of the cable not compensated

by the decrease of mass per unit length.

CONCLUSIONS

1. A method for modeling the distribution of current

density and temperature over OPGW cross-section

manufactured by the TU STO 71915393-

Т

U 113-2013

and veri

fi

ed by the results of environmental tests in HV

EC of JSC FGC UES was developed.

2. Use of galvanized steel wire in the plastically

deformed OPGW outer layer under 1-second 4.3 kA max

fault current passage allowed to reduce the temperature on

the surface of the optical module by 35°

С

compared with

an uncoated steel wire rope.

Aluminum coating allows to make additional

reduction of temperature but its use is associated

with a number of negative factors: the low corrosion

resistance of aluminium coating in the contact area with

the optical module stainless tube; low lightning strike

withstandability of aluminum wire.

When it comes to choosing which

type of protective coating to use for steel

wires it should be taken into account not

only the possible change of temperature

fi

elds in OPGW under the same values

of fault current, but also dependence

of its size on speci

fi

c resistivity of the

shield wire, as well as lightning current

withstandability, corrosion resistance

and carrying capacity of the shield wire.

REFERENCES

1. Tro

fi

mov B.L., Features when

choosing optical cable for overhead

transmission lines / B. L. Tro

fi

mov, D.

M. Indebaum // Power engineering

and industry of Russia, 2012, No 12,

(200). P. 29.

2.

Study of lightning strike and

mechanical impact withstandability

of shield wires / A.K. Vlasov, V.A.

Fokin, V.F. Danenko, V.I. Frolov,

E.Yu. Kuskina // Steel. — 2003, No 9,

P. 66—70.

3. Mekhanoshin B. I. An integrated approach to ensure

OHL lighting-surge proofness / B.I. Mekhanoshin,

O.I. Bogdanova, M.Z. Ghiliazov, D.A. Matveev. —

Transactions of the Russian III Conference on Lightning

protection. St. Petersburg, May 22—23, 2012, http://

lightningprotection.ru/wp-content/uploads/ — 22—

23 May 2012. Pdf.

4. Rules of Designing, Construction and Operation

of Fiber Optic Communication Line in Overhead

Transmission Lines with Voltage 110 kV and Higher.

M.: RAO UES of Russia, 1999. 108 p.

5. Vlasov A.K., On strengthening service properties

of shield wires for lightning protection of overhead

electrical power lines / A.K. Vlasov, V.A. Fokin, V.V.

Petrovich, V.I. Frolov, V.F. Danenko // Steel. 2011,

No 7, p. 78—81.

6. Pat. 2441293 C1 RF, IPC H01 11/22. Shield wire

with

fi

ber-optical communication cable. / Vlasov

A.K., Fokin V.A., Petrovich V.V., Frolov V.I. applied

03.11.2010, publ. 27.01.2012. Bul. No 3.

7. STO 71915393-

ТУ

113-2013. Severstal-Metiz. Steel

ropes (ground wire) to protect the overhead power lines

from direct lightning strikes. Technical conditions.

Volgograd. 2008.

8. STO 56947007-29.060.50.122-2012 JSC FGC UES

Guidance on calculation of melting ice on overhead

ground-wire cable with integrated optical cable

(OPGW) and application of the distributed temperature

control in OPGW melting. Effective date: 05.18.2012,

JSC FGC UES2012, p. 119.

9. Methodological guidelines for calculating thermal

stability of OHL shield wires. M. Energosetproekt.

1976.

Оригинал статьи: Temperature and Grid Control Density Simulation in Overhead Ground Wire Cable with Fiber Cable (OPGW) under Short Circuit Current Passage

Along with the standard information fiber optic cables (FOC), made with dielectric self supporting cables, overhead ground-wire cables made of steel wires with different coatings containing stainless steel module which comprises optical fibers in hydrophobic semi-liquid gel are widely used (OPGW). This design provides necessary mechanical strength and is a product of dual purpose: it performs the traditional role of protecting power lines from lightning strikes and used as communication and data transfer cable.