The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

62

August 25–29, France, Paris

Innovations

M

oscow energy system supplies power to

consumers in the territory of Moscow City

and Moscow Region, with the total area

of 47 000 m

2

and population of over 19

million people.

The absolute load peak value of Moscow energy system

reached 18052 MW (historical peak), power consumption

in 2012 amounted to about 100.9 TW•h (about 44% of

IES of Center power consumption, which corresponds to

nearly 10% of UES of Russia power consumption).

Power grids 750, 500, 220, 110 kV and below, which

include 566 substations (2 — 750 kV, 11 — 500 kV,

90 — 220 kV, 463 — 110 kV; installed transformer

capacity of about 65 thousand MVA), 998 transmission

lines with total length of approximately 16700 km, operate

in the territory of Moscow energy system.

A characteristic feature of Moscow energy system is

basic power

fl

ows from north to south. This is explained

by the fact that basic electric power sources are located in

the north and north-west of IES of Center.

According to JSC “Energosetproyekt Institute”, the

existing power balance of IES of Center re

fl

ects on the

load of OHL and CL between the northern and southern

parts of Moscow energy system, which manifests itself

in a decrease of the total capacity of backbone networks

between Moscow energy system and other energy systems

included in IES of Center. In this case there are transit

power

fl

ows in 110 and 220 kV grids between the northern

and southern areas of Moscow. Such a situation is believed

to remain in the nearest and long-term perspectives.

Increasing capacity of links between the northern

and southern areas of the metropolitan city will require

increasing the number of lines 220 kV or construction

of load-center substations 500 kV, with their connection

to load centers 500 kV located along the Moscow ring

500 kV.

During construction of new parallel transmission

lines 500 kV there arise dif

fi

culties related to allocation

of land for line routes, as main backbone lines 500 kV,

which require reinforcement (doubling), are located in

close proximity to the city, with its ongoing mass housing

construction.

At present, power supply of Moscow central area is

mainly carried out by means of cable transmission lines

(CL). The consumer load amounts to approximately 2000

MVA and is covered by means of receiving power from

feeder centres, located in the city periphery (substations

500 kV “Ochakovo”, “Chagino”, “Beskudnikovo”, large

TPPs). Increasing demand for electricity causes a relevant

problem of meeting this demand, which can be solved by

creating additional power sources (construction of power

plants) and construction of load-center substations.

Since construction of power plants in the city center

requires allocation of extensive territories, while their

Prospects of Implementation

of Electrotechnical Equipment

with Superconductivity

Technology Elements in JSC

"UNECO"

Andrey MAYOROV (

Андрей

МАЙОРОВ

), General Director,

Vitaly NAUMOV (

Виталий

НАУМОВ

),

Head of Department of Advanced Projects, JSC “United Energy Company”,

Sergey SAMOYLENKOV (

Сергей

САМОЙЛЕНКОВ

), General Director,

CJSC “SuperOx”

63

info@eepr.ru, www.eepr.ru

operation can impair ecology and architecture of the area,

one of alternatives is increasing capacity of transmission

lines, which can be achieved by increasing voltage and/or

rated operating current.

One of radical problem solutions might be the variant

of transfer to a higher voltage level — 500 kV, developed

by JSC “Energosetproyekt Institute”: construction of

an overhead line — 500 kV (OHL 500 kV), capable of

transmitting power of up to 2000 MVA; however, this

variant is unacceptable in the city center.

Construction of a cable line 500 kV (CL 500 kV) in

ground or a tunnel does not require allocation of extensive

territories; however, comparing to OHL 500 kV, its speci

fi

c

capacitance is 12—15 times as high. Compensation of

reactive power generated by CL 500 kV requires installing

compensating devices (FACTS) with total capacity of

approximately 900 MVA. Placing such equipment (with

monitoring and

fi

re-extinguishing systems) at substation

sites in the city center is extremely undesirable.

A promising solution to the load-center problem

in Moscow central districts is implementation of gas-

insulated (gas-

fi

lled) transmission lines (GIL), in which

SF6 dielectric gas is under excessive pressure.

One of the

fi

rst industrial installations GIL 420 kV

was developed by Siemens and commissioned in 1975

at Wehr Pumped Storage Hydroelectric Power Plant in

Schwarzwald Mts. (Baden-Wurttemberg state). GIL pipe

diameter for a single-phase line 400 kV is approximately

500 mm, and three pipes are required for a three-phase

line. As for the underground version, the tunnel size for

two three-phase GIL should correspond in diameter to

3.5 or 2.5 m in height and 2.8 m in width. One should

note that in the 70s of the last century in our country

GIL 110 and 220 kV were designed, manufactured and

put in pilot operation, which was followed by bench

tests of GIL 500 kV. However,

inadequate technology lying

in the basis of these devices

impeded their promotion onto

Russian market.

Another variant suits for crea-

tion of high-capacity transmis-

sion lines, and this is implemen-

tation of superconductors.

Superconductivity, i.e. disap-

pearance of electric resistance in

a number of materials at low tem-

peratures, was discovered in 1911,

but search for ways to produce us-

able materials lasted for almost

half a century. Niobium-based

superconductors appeared only in

1960s and quickly occupied their

place in powerful magnetic sys-

tems (medical CT scanners, accel-

erators). Use of these supercon-

ductors in power engineering was

considered and prototypes of cable systems were designed;

however, a need in using expensive liquid helium and com-

plex cryogenic systems prevented this technology from be-

ing put into practice. The situation changed at the end of

1980s after discovery of superconductivity in ceramic com-

pounds. Superconductors of this family have an abnormally

“high” temperature of transition into superconductive state,

which can vary from 90 to 130

К

(-143 — -180

о

С

) for vari-

ous substances. This means that there emerged a possibility

of using liquid nitrogen instead of unrenewable expensive

liquid helium for cooling superconductors to operating tem-

peratures. New superconductors were called high-tempera-

ture ones (HTS).

Among HTS conductors, several cable systems have

been designed and put in pilot operation in Germany, USA,

Korea, Japan and other developed countries (Fig.1, 2, 3).

Operation within a real grid demonstrates high reliability

of these systems.

An important factor enabling signi

fi

cant simpli

fi

cation

of HV insulation of HTS cables is very high dielectric

strength of liquid nitrogen, which is used as a cooling

agent (10—50 kV/mm, depending on pressure, nitrogen

purity and geometry). These values are comparable to

dielectric strength of transformer oil, which makes it

possible to greatly reduce the thickness of insulation layer

and HV cable size.

Main advantages of superconductive cable lines, in

addition to their compact size, are the following:

•

no electromagnetic

fi

eld outside the cable. As a rule

,

HTS cable design includes a shield of HTS tapes,

which prevents radiation from penetrating outside the

cable sheath. In particular, this enables laying HV CL

in ground;

•

no heat release

. Due to the fact that superconductor

operating temperature is extremely low, HTS cables

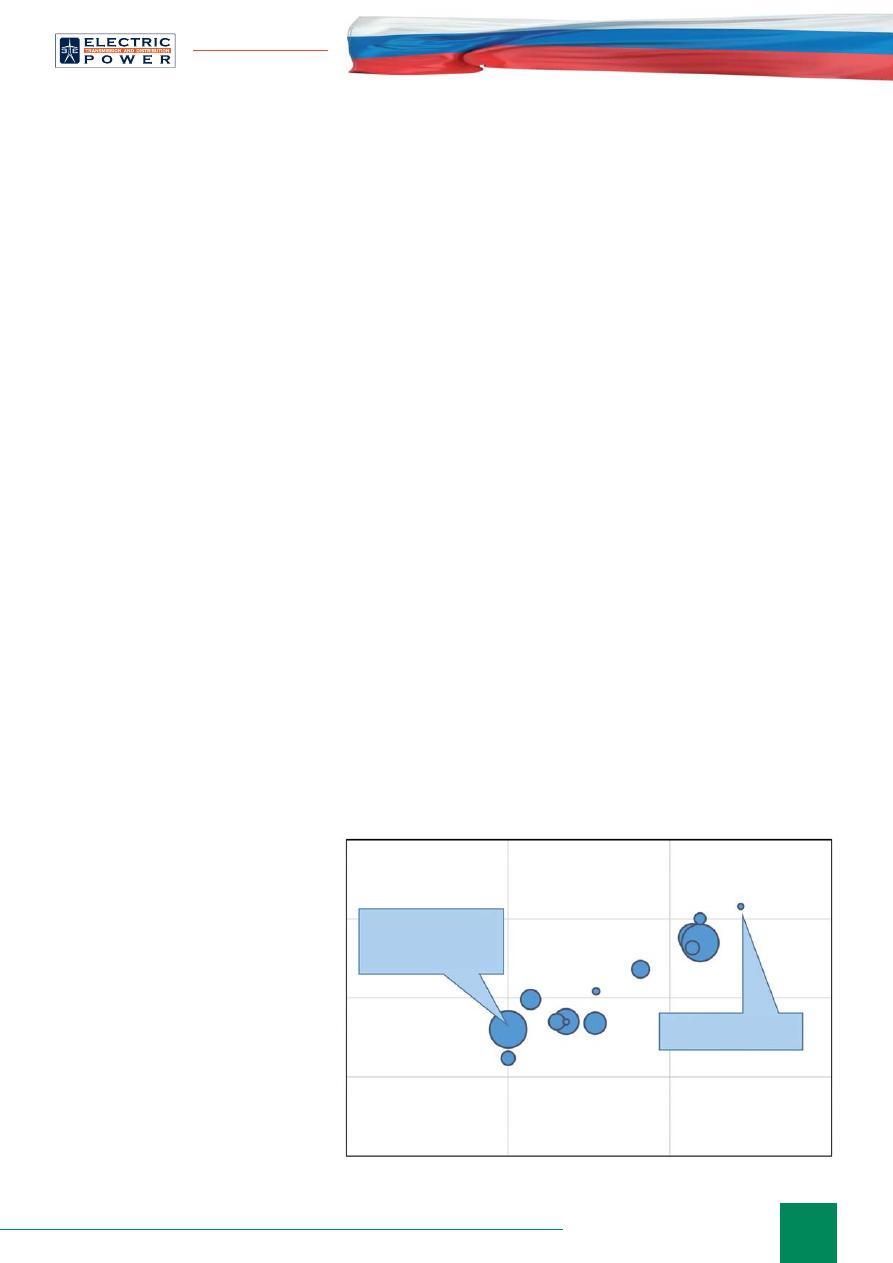

Fig. 1. AC HTS CL characteristics. Spot area is proportional

to the cable line length

AMPACITY project

Essen, Germany

10 kV/40 MVA/1000 m

Furukawa, Japan

275 kV/1500 MVA/30 m

1

10

100

1000

10000

1000

100

10

1

Voltage (kV)

Power (MV

A)

64

August 25–29, France, Paris

Innovations

have vacuum thermal insulation of a very high level.

Therefore, the temperature of cable system outer layer

approximates the ambient temperature. This makes it

possible to locate parallel cable HTS lines or phases in

close proximity to each other;

•

long service life

. The basic criterion that limits service

life of HV cables is insulation aging, which accelerates

at temperature rises (current increases). Since HTS

cables are operated at cryogenic temperatures, at which

negative insulation aging processes are very slow, the

expected service life of HTS CL exceeds service life of

standard cables many times.

Another useful property of HTS CL is relatively

low values of inductance and capacitance. Owing to it,

high power can be transmitted over HTS cables without

compensating devices for long distances (hundreds of

kilometers). In this regard, HTS CL is inferior only to an

overhead transmission line. Table 1 shows values of basic

parameters of OHL 380 kV, XLPE-insulation cable and

HTS cable, according to [1].

It should be noted that technologies of construction

of HTS cable systems have already been mastered in

Russia. In 2007—2010 a group of developers (JSC

“VNIIKP”, JSC “ENIN”, Moscow Aviation Institute,

JSC “R&D Center for Power Engineering”) designed

and manufactured an HTS cable, which at the time was

the longest in Europe (20 kV, 50 MVA, 200 m) [2]. JSC

“FGC UES” is vigorously developing a project of creating

the world’s longest DC HTS CL in St. Petersburg (20 kV,

50 MVA, 2500 m). Second-generation HTS conductors

are manufactured in CJSC “SuperOx”; in 2013 two model

cables with critical currents 3 and 4.5 kA were designed

in JSC “VNIIKP” on the basis of such conductors [3,4].

As applied to Moscow energy system, superconductive

cable lines can be implemented for introducing high power

to the city center with the use of existing infrastructure

or with its slight changes. For example, three phases

of a cable with operating voltage 275 kV developed by

Furukawa Company enable transmitting power of about

1500 MVA, and such a cable line can be placed in a cable

duct with 1 m width and 0.50 m height. The conductor

current-carrying capacity can be increased by using a

larger quantity of HTS conductor up to min.10 k

А

.

Thus, one can conclude that creation of a three-phase

AC HTS CL with operating voltage 220 kV and transmitted

power of 2000—3000 MVA is fully implementable

from the technical point of view. Such a line would be

a supercompact, energy-saving and ecological solution to

the above-described problem.

Development of electric energy systems (EES) is

closely related to the general economic development

and is characterized with sustainable growth of electric

loads, corresponding increase of generation capacities,

reinforcement of connections with adjacent EES

and creation of large interconnected systems, which

interconnect not only territories of separate countries but

also whole continents. An inevitable consequence of such

development is growth of short-circuit currents, which is

especially acute in high power consumption density areas

and metropolitan cities.

Another main problem related to grid operation in

Moscow energy system is high fault current values.

Calculations carried out in JSC “Energosetproyekt

Institute” showed that, with the existing grid

sectionalization, by 2020 fault currents in Moscow energy

system will exceed the following values:

• 63 kA on 16 existing and newly constructed energy

facilities 500 and 220 kV;

• 80 kA on 10 energy facilities 500 and 220 kV.

At present, the basic undertaking to limit fault currents

in Moscow energy system is sectionalization of the grid

110 and 220 kV.

A signi

fi

cant number of existing sectionalization points

of 110—220 kV grid and impossibility to increase the

Fig. 2. Phase of HTS cable manufactured by

Furukawa (Japan, 2013). Outer diameter 150

mm, voltage 275 kV, three-phase CL capacity

1500 MW

Fig. 3. Three-phase coaxial HTS cable 10 kV

manufactured by Nexans (Germany, 2014). Outer

diameter about 150 mm. CL capacity 40 MVA

65

info@eepr.ru, www.eepr.ru

number due to conditions of providing

reliable power supply of consumers

cause need in developing and taking

technical measures on limiting fault

currents.

Cost of a circuit-breaker with

operating breaking current 80 kA and

its size exceed the cost and size of

the existing circuit-breaker with rated

breaking current 63 kA almost twice,

which is a great obstacle for placing

such equipment at limited-space

substation sites in the city.

Thus, max. permissible level of

fault currents for Moscow energy

system should be 63 kA, and switching

equipment with rated breaking current

80 kA can be implemented only in

certain cases. Primary attention should

be paid to measures on limiting fault

currents.

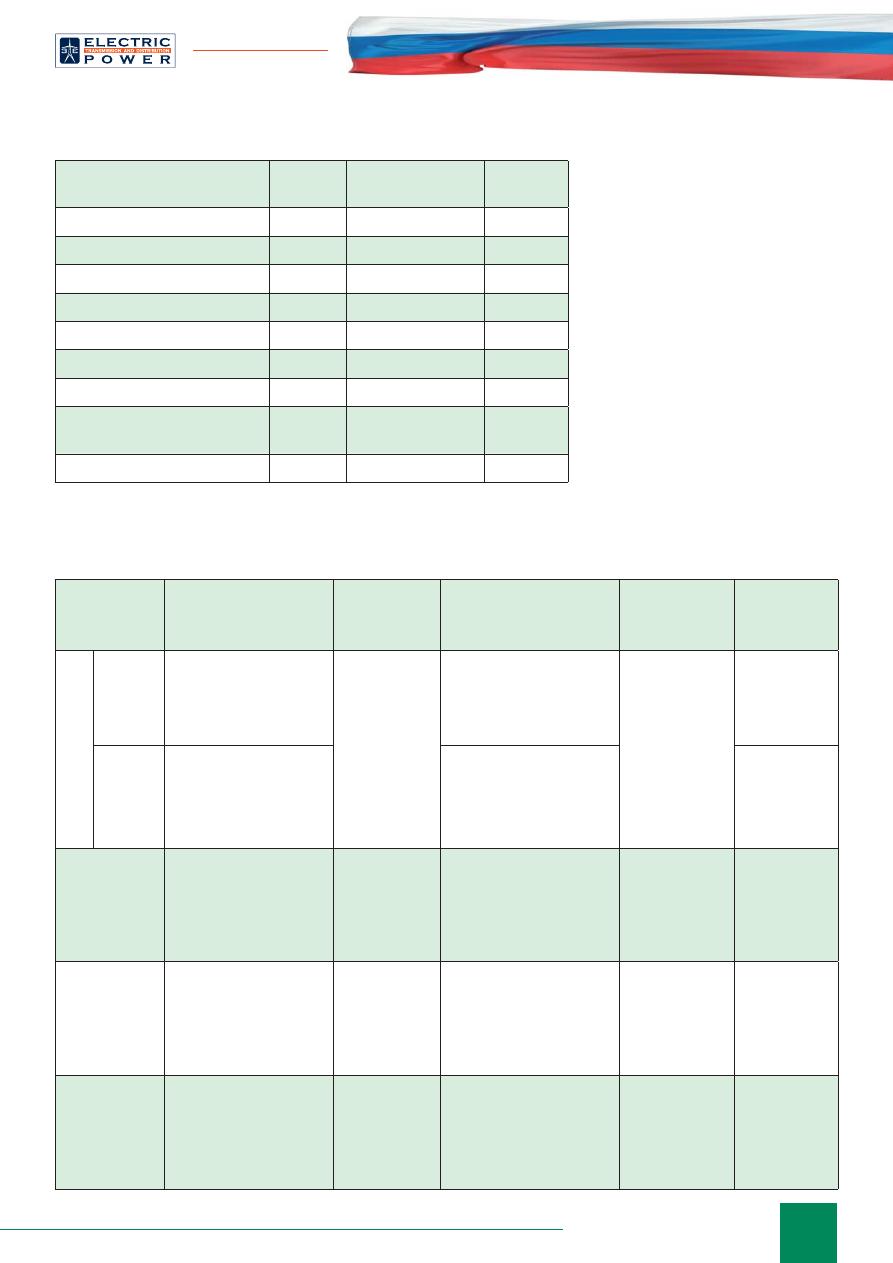

Table 1. Comparison of characteristics of transmission lines

380 kV designed as OHL, XLPE-insulation cable and HTS CL

Parameter

OHL

XLPE-insulation

cable

HTS CL

Transmitted power, MVA

1645

1185

3290

Rated current, kA

2.5

1.8

5.0

Peak current, kA

3.0

—

10.0

Inductance, mH/km

0.879

0.470

0.215

Capacitance,

μ

F/km

0.0132

0.202

0.106

Resistance, mOhm/km

23.3

10.9

0.0004

Speci

fi

c impedance Z, Ohm

258

48

45

Load wave impedance (U2/Z),

MVA

559

2994

3200

Critical length

***

, km

2749

122

686

***

critical length is based on line speci

fi

c capacitive current values

Table 2. Technical and economic comparison of Moscow energy system development scenarios with

account for measures to limit fault current levels

Scenarios

Measures

Imple-

mentation

results

Negative sides

Need in CB

replacement,

pcs.

Imple-men-

tation cost,

million euro

Scenario 1 “Conventional”

Base-

case

variant

Installation of current-

limiting devices in

110 and 220 kV grid

40 kA and

below

No production of current-

limiters (CL) utilized

in the industry. No area

for placing CL at grid

facility sites

500 kV — 24

220 kV —199

110 kV — 491

720

Alterna-

tive vari-

ant

Creation of additional

sectionalization points

in 220 kV grid, installa-

tion of CLR in

110 kV grid

Increasing grid

sectionalization points

680

Balancing

Sectionalization of

Moscow City 110 and

220 kV grid into

4 parts

40 kA and

below

Decrease in reliability of

power supply of consum-

ers and power output of

power plants in repair

and post-emergency con-

ditions, need in ALT

500 kV — 24

220 kV — 117

110 kV — 378

500

External

Installing HVDC links

in OHL 500 kV inter-

connecting generation

facilities of IES of Cen-

ter and Moscow ring

500 kV substations

Redu-cing

fault currents

only in 500 kV

grid

No impact on fault

current levels in 220 and

110 kV grid

—

1800

HVDC links

and load

centers

Installing HVDC links

in 220 kV grid and

radial operation of

110 kV grid

Moscow—

40—50 kV,

Moscow

Region —

40 kA and

below

Need in extensive

territories for installing

HVDC links. Need in

ALT

500 kV — 22

220 kV — 145

110 kV — 407

1000

66

August 25–29, France, Paris

Innovations

Based on the conducted analysis of foreign experience

in construction of grids in metropolitan cities and

implemented methods and means of limiting fault current

levels, the following four scenarios of Moscow region grid

development with fault current limiting were developed:

conventional, balancing, external ones, HVDC links and

load centers.

Main results of technical and economic comparison

of the described scenarios of Moscow energy system

development with fault current limiting are shown in

Table 2.

The problem of limiting fault currents is relevant

for all countries of the world. Almost all large-scale

power engineering companies, international research

organizations such as CIGRE

и

IEEE, R&D centers and

higher educational establishments in many countries,

including Russia, try to solve this problem.

Development of new technologies and materials,

related to converter equipment and superconductivity

phenomenon, rapid progress in element base of power

electronics and high-temperature superconductive

materials (HTS) make it possible to develop current-

limiters (CL, Fig. 4), HVDC links and HVDC transmissions

(Fig. 5), FACTS, new-generation energy accumulators

with properties that give way to wide implementation of

such devices in power industry.

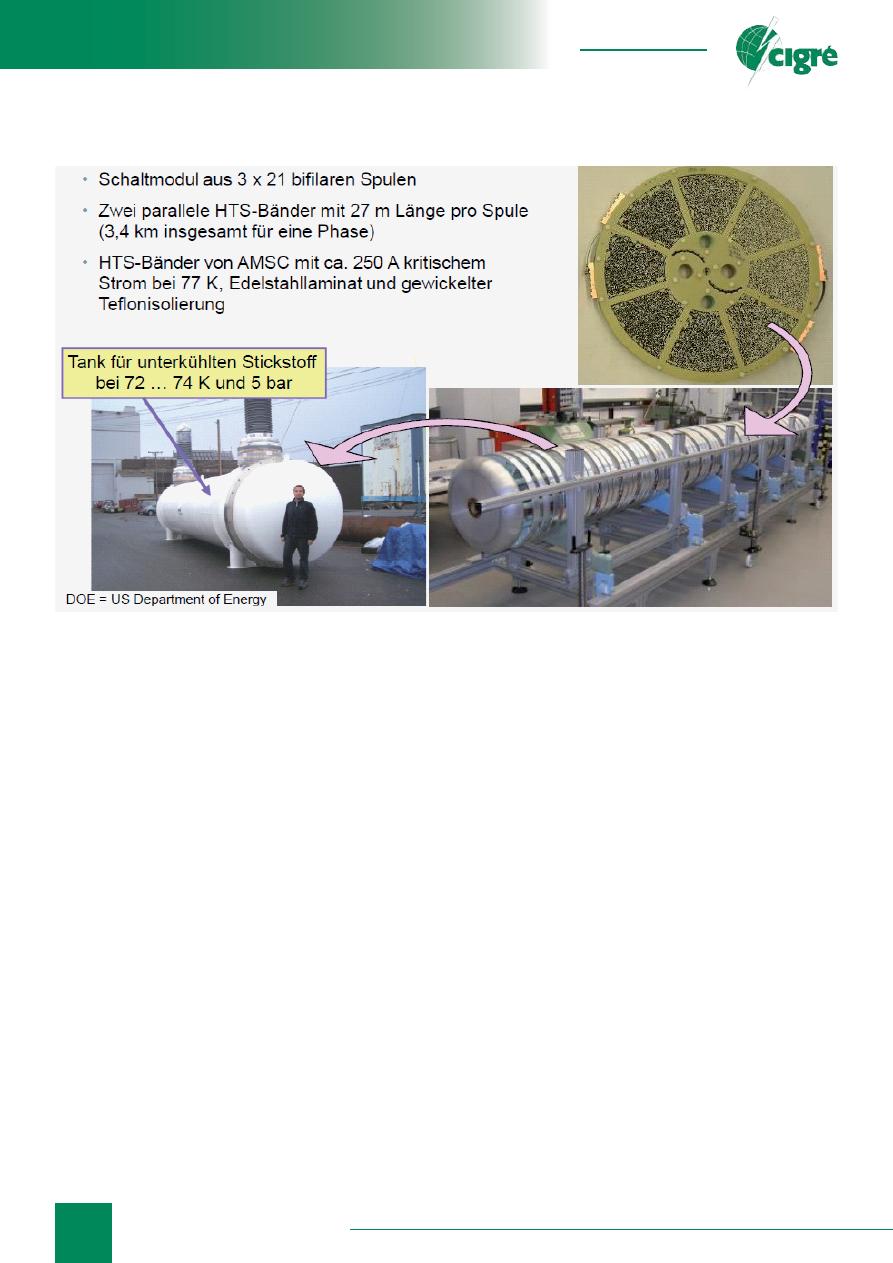

By present, more than 15 prototypes of superconduc-

tivity-based electrotechnical equipment for limiting of

fault currents have been designed and tested in the world.

Operation of these devices is based on the superconductor

property to transition from zero-resistance state into

fi

nite-

conductivity state when some speci

fi

ed critical current

value is exceeded. Transition from low-resistivity state

into high-resistivity one does not require external control

and happens very quickly (characteristic operation time

is about 1 ms), which is a key advantage of such systems.

Fault current limiters are actively developed in

Germany, Italy, USA, South Korea, China. For example, a

fault current limiter, designed for 24 kV/1 kA, was installed

in 2013 as a busbar switch 15 kV of adjacent transformers

on Majorca Island, Spain (ENDESA grid company); this

device was manufactured by Nexans Superconductors

(Germany). A fault current limiter, designed for

115 kV/900 A, was developed by Siemens (Germany),

now this device is in pilot operation in USA grid

(see Fig. 4). KEPRI, Korea, is designing a superconductive

current-limiter for 154 kV/2 kA to be installed in KEPCO

grid; its tests are scheduled for 2014. In China in 2011 an

HTS inductive fault current limiter, designed for 220 kV

and 800 A, was commissioned on Shigezhuang substation

(Tianjin).

As it was stated earlier, the issue of limiting fault

currents in 110 and 220 kV grids of Moscow energy

system is extremely acute. Therefore, implementation

of breakthrough technologies based on high-temperature

superconductors is especially relevant for Moscow City.

Installation of a current-limiting reactor (CLR) 220 kV

on “Mnevniki” substation was included in an investment

program of JSC “UNECO”. Projects of construction of

cable lines 220 kV also highlight the need in installing CL

Fig. 4. Components of CL superconductive switch 154 kV developed by Siemens

for the American energy system

67

info@eepr.ru, www.eepr.ru

on “Vagankovskaya”, “Novobrattsevo”, “Tsentralnaya”,

“Choboty” and other substations. JSC “UNECO” works

on the issue of installing a CL superconductive switch,

designed for 220 kV, on “Mnevniki” substation. Design

and integration issues were discussed with specialists

from Germany, South Korea and Russian company CJSC

“SuperOx”.

In conclusion, it should be stated that JSC “United

Energy Company”, while keeping to the line of sustainable

development of its power supply facilities, integration of

innovative technologies and equipment, participates, on a

permanent basis, in events that bring together Russian and

foreign power industry specialists.

JSC “UNECO” suggests further works on the issue

of construction of load-center substations fed by cable

superconductive lines 220 kV with capacity of 2—2.5

GW. With other conditions being equal, it is evident that

construction costs for 220 kV HTS CL will be lower due

to smaller sizes of cable tunnels.

Use of superconductive current limiters in 220 kV grid

will make it possible to solve the urgent problem related

to growth of fault currents in energy systems.

As part of its innovative activities, JSC “UNECO” also

intends to develop new projects based on implementation

of superconductive equipment, such as:

• superconductive energy accumulators with capacity

of 0.5—1.0 MW•h, for backup power supply of

residential consumers of metropolitan cities;

• construction of high-capacity grids 20 kV in Moscow.

Applied superconductivity has another, equally

important from the point of view of prospective

application

fi

elds, side, conventionally called low-

current applied superconductivity or superconductive

electronics. For example, with implementation of SQUIDs

(superconducting quantum interference devices), a new

generation of non-destructive evaluation magnetometering

systems, required, in addition to atomic, aviation and space

industries, for PD monitoring and diagnostics of insulation

structures in power engineering, is under development.

CONCLUSION

1. Technical grounds for implementing superconductivity

technologies in power engineering and power industry

have been well established by now.

2. Potential for wide implementation of energy-

ef

fi

cient superconductivity technologies is explained

by the fact that total losses at all stages (power

generation, distribution, consumption) can be reduced

2.5 times, with simultaneous reduction of consumption

of materials for devices and units 2—3 times

only by replacing conventional equipment with

superconductive one.

3. Implementation of the above described programs

requires developing

fi

nancial support models of

investment projects.

4. Taking into account the signi

fi

cance of superconductivity

technologies for a whole range of industries (power

industry, military equipment, transport, medicine,

megascience), a multi-target system of technology

development support with state participation should be

contemplated.

5. The task of developing superconductivity technologies,

being an integral part of the innovative constituent of

Russian power industry development, is relevant and

requires immediate solution.

REFERENCE LITERATURE

1.

R. Zuijderduin, O. Chevtchenko, J.J. Smit,

G. Aanhaanen, I. Melnik, A. Geschiere, AC HTS

transmission cable for integration into the future EHV

grid of the Netherlands, Physics Procedia 36 ( 2012 )

1149—1152.

2. V.S. Vysotsky, A.A. Nosov, A.V. Rychagov, V.E.

Sytnikov, S.S. Fetisov, K.A. Shutov, Development of a

superconductive power cable based on

HTS technologies. Project development

and results, Cables and Conductors,

2010,

№

3, p. 3.

3.

S. Lee, V. Petrykin, A. Molodyk,

S. Samoilenkov, A. Kaul, A. Vavilov, V.

Vysotsky, S. Fetisov, Development and

production of second generation high Tc

superconducting tapes at SuperOx and

fi

rst tests of model cables, Supercond.

Sci. Technol. 27 (2014) 044022.

4.

.S. Vysotsky, S.Yu. Zanegin, V.V.

Zubko, A.A. Nosov, G.G. Svalov, S.S.

Fetisov, S.R. Lee, S.V. Samoylenkov,

First models of current-carrying

conductors of superconductive cables

manufactured with the use of Russian

second-generation HTS tapes and

results of their tests, Cables and

Conductors, 2013,

№

6, p. 26.

Fig. 5. Components of an HVDC link

Оригинал статьи: Prospects of Implementation of Electrotechnical Equipment with Superconductivity Technology Elements in JSC “UNECO”

Moscow energy system supplies power to consumers in the territory of Moscow City and Moscow Region, with the total area of 47 000 m2 and population of over 19 million people.