The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

2014

DIGEST, February, 2014

32

Digital substations

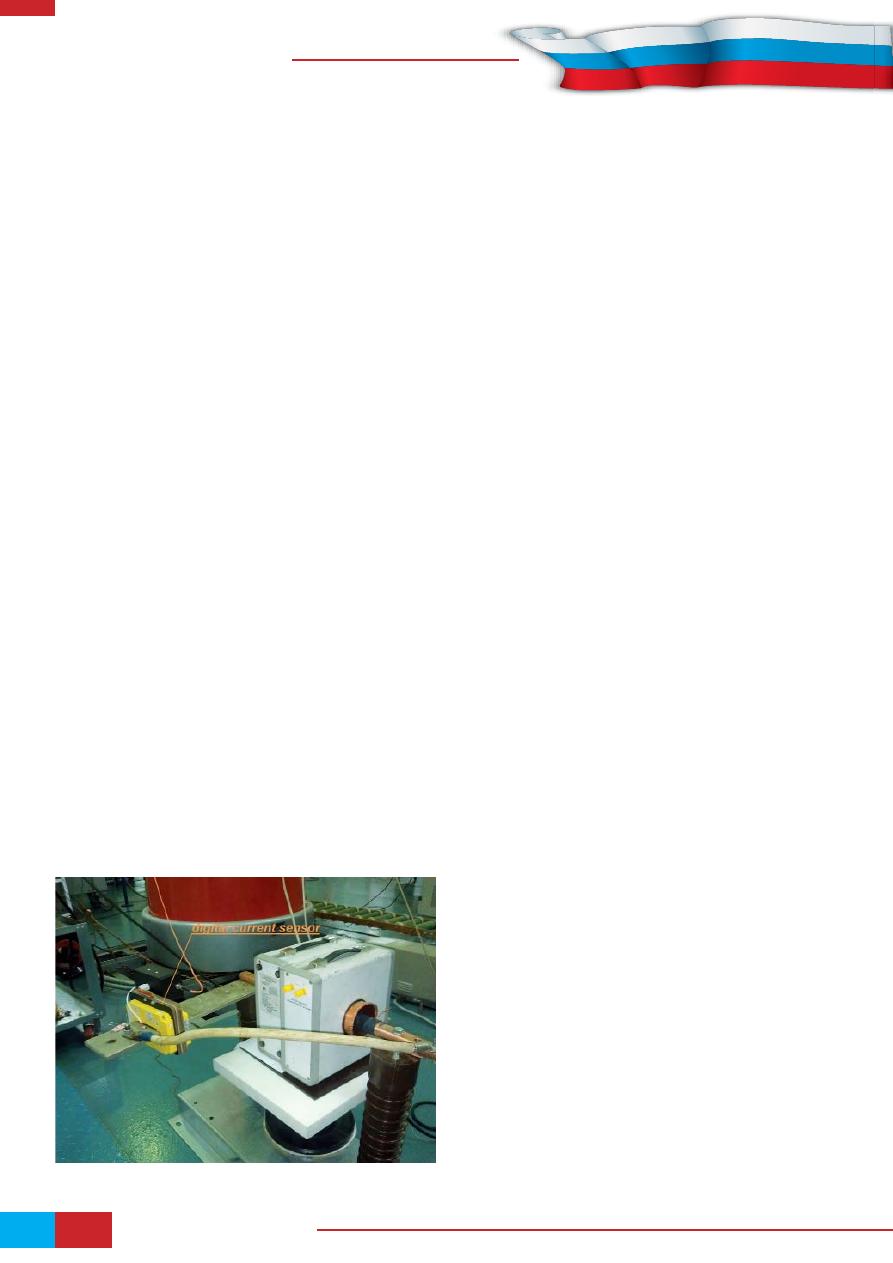

Digital sensor high-voltage test (35 kV).

A

few years ago the terms “smart grid” or “digi-

tal substation” could be used only by young

enthusiastic specialists as something very far.

But interest in smart grid inevitably

grew, pro-active research, testing and development were

carried out, and today the Government has made several

strategic documents determining energy development in

Russia. “Policy objective will be creation of intelligent

electric grid complex with active-adaptive power system

— new generation customer-oriented network based on

the multi-agent control principle on the basis of mass

balanced implementation of modern technological tools

and solutions in the complex”, as set out in “Development

Strategy of the of electric grid complex.” Thus, all

the approved government documents directly refer us

to creation of "Smart grids" in Russia, where digital

substation are the key part.

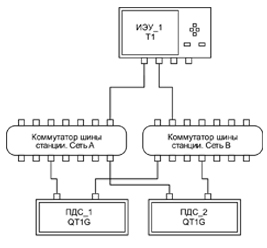

In correspondence with IEC 61850 «Communication

Networks and Systems in Substations» a digital substation

has three levels:

•

process

level;

•

bay

level;

•

station

level.

The station and bay levels are the most widely covered

and elaborated by Russian and foreign enterprises.

These levels are responsible for control, monitoring,

storing and distribution of data. Process level is not

paid so much attention to, although it is responsible for

collection of primary analog and discrete data, that is,

Process level development strategies

Dmitry UKRAINSKIY (Дмитрий УКРАИНСКИЙ), Leading Engineer,

Alexander ZHUKOV (Александр ЖУКОВ), Director General,

TERMA-ENERGO LLC leading engineer

primary information. This includes current and voltage,

presence or absence of voltage, busbars and transformer

temperature, cables insulation resistance and other

signals. Some of the most important decisions are made

basing on this information, so it must not be forgotten

that modernization and development of sensors collecting

primary information in substations is very important.

Our company has secured its place in the market

and established itself as a manufacturer and supplier of

quality components for power industry, such as voltage

detectors, voltage arc protection devices equipped with

f iber-optical sensors, voltage dividers, and others.

Also, our company develops and manufactures various

products for 6—35 kV electrical equipment using epoxy

compounds (post and entrance insulators, busbars). To do

this TERMA-ENERGO LLC uses latest 3D technology

for insulator and injection moulds design as well as

modern equipment and technological processes acquired

from the world leaders in this field, such as Hübers,

Vogel, Hedrich, Huntsman. This combination allows

TERMA-ENERGO to maintain high product consumer-

grade.

Development of modern element base and the adop-

tion of new international standards provided a good op-

portunity for our developers to use innovative approaches

to gathering primary information necessary to create ad-

vanced digital substations. Based on the existing problems

in the world experience in running the digital stations, a

clear understanding and concept to establish a harmonized

set of devices for collecting primary information has been

generated. Today it is one of the priority directions of

TERMA-ENERGO activity. This primarily concerns ac-

quisition of current and voltage data for commercial ac-

counting and protection.

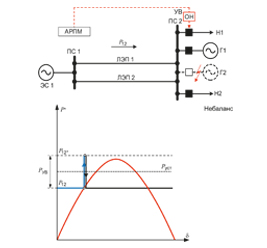

Contrary to popular belief about the preferential use of

digital optical transformer at the substation process level

we should not forget that such transformers are most ap-

propriate and effective at high and extra high voltages.

While at medium and low voltages due to their high cost

and low sensitivity these transformers are not effective.

On the base of lengthy research our company has been

successful in developing high accuracy current and voltage

sensors outputting digital optical signals of currents and

voltages measured in real time. Workable specimens were

obtained and test results proved their effectiveness.

Current sensor consists of a specially designed high-

precision, high-speed and jam-protected analog-to-

www.eepr.ru

33

digital conversion board and original

measuring elements. All of this is placed

on high potential side, does not require

insulation and additional power source.

Thus, only an extra strong dielectric

fiber optic cable with two optical fibers

providing galvanic isolation is routed

to low potential side.

The first fiber transmits billing cur-

rent values of 0.2s accuracy [1] / 256

samples/cycle; the second fiber trans-

mits 10p accuracy [1] current data /80

(90) samples/cycle for relay protection

units.

The current output signal ratio for

relay protection device is 8000% of rated primary current.

Operating temperature range is -40° to +85° C. The rated

primary current is up to 5000 A.

Overall dimensions and weight of the current sensor is

relatively small and can be commensurate with the classic

measuring current transformer for 0.66 kV voltage. There-

fore, mechanical strengthening of high-voltage bus to in-

stall the sensor is not required. Dimensions and weight al-

most do not change under the increase of the rated current

within 10—110 kV voltage class. As for the cost of the

current sensor, it is a sequence lower in comparison with

cost of transformer based on optical laws and commensu-

rate with cost of classical measuring current transformers

starting from 10 kV voltage class.

Currently voltage sensor has an accuracy of 1%, and

operates within -25 º — +50 º C temperature range. This

sensor features a smaller dimensions and lower cost com-

pared to existing measuring voltage transformers, it has

no DC magnetizing and resonance phenomena inherent to

classical voltage transformers. Work is underway to in-

crease the accuracy of the sensor to class 0.2 [2] for use in

commercial accounting of electric circuits. Digital output

is similar to the output of current sensor.

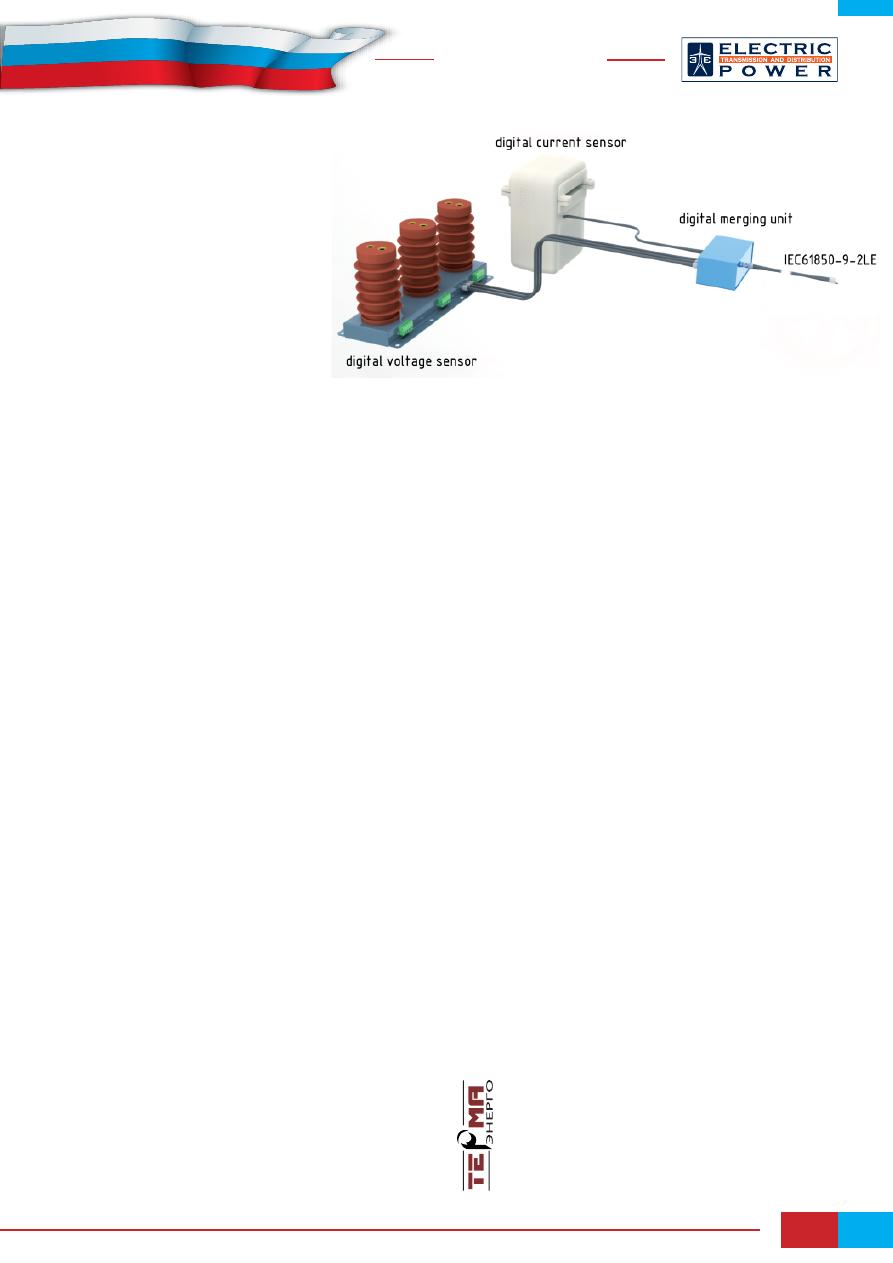

To work on IEC 61850 standard these current and

vol-tage sensors require digital Merging Unit, capable of

receiving input digital optical signals and form a group

digital stream protocol per IEC 61859-9-2LE standard.

Using only digital signals, the accuracy of the informa-

tion received is maintained as digital optical signal car-

rying information from the transformer is not affected by

electromagnetic interference and, in addition, there is no

analog-to-digital conversion, which inevitably introduces

additional error. Moreover, lack of an analog-to-digital

conversion greatly simplifies Merging Unit and reduces

the dimensions.

In accordance with policy we seek to identify and work

through the most weaknesses and continuously engaged

in the development of sensors to collect other valuable in-

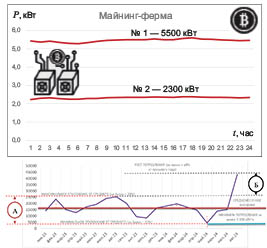

formation except for current and voltage. The next device

to be launched into serial production will be a tool for on-

line measurement of insulation resistance of cable lines.

Due to constant connection of the device to high voltage,

the time available for the measurement of this parameter

takes about 5 minutes as opposed to the currently existing

devices that perform the same task. The output signal may

support GOOSE-messages.

Feasibility studies undertaken suggest that the cost of

our equipment during the transition to serial production

will not exceed the cost of conventional solutions and will

provide a number of technical advantages:

•

improving measurement accuracy and information

transfer reliability;

• simplicity of design, operation and maintenance;

• unified platform data exchange (IEC 61850);

• high noise immunity;

• high fire explosion and ecological compatibility;

• digital signal in real time;

• absence of saturation and ferroresonance;

• small size and weight of the primary equipment;

• reduction in the number of copper cable connections,

number of devices, as well as more compact arrange-

ment.

So, due to the advent of IEC 61850 standard unified

data exchange platform made a reality transfer of

information using innovative devices, including digital

current and voltage transformers. However, a number

of questions remains to be solved and full integration of

these technologies providing smooth operation needs a

joint effort of manufacturers and developers operating in

the field of digital substations. Our company is open for

cooperation.

LITERATURE:

1. GOST 7746-2001 “Current transformers. General

specifications”

2. GOST 1983-2001 “Voltage transformers. General

specifications”.

Ltd, Bldg 3, Dudko str., Saint-Petersburg, 192029

Tel. +7 812-640-11-28, +7 812-346-50-09

http://terma-energo.ru

ukrainskiy@terma-spb.ru

Оригинал статьи: Process level development strategies

A few years ago the terms “smart grid” or “digital substation” could be used only by young enthusiastic specialists as something very far. But interest in smart grid inevitably grew, pro-active research, testing and development were carried out, and today the Government has made several strategic documents determining energy development in Russia.