The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

3 - 6 J U N E 2 0 1 9

MADRID, SPAIN

30

Effi

ciency of Implementing

Domestic Innovative High-

strength and High-temperature

Steel-Aluminum Сonductors

PJSC "Rosseti" maintains 44 thousand km of new conductor

types or 1% of the total conductors' length (4.5 million km).

Self-supporting insulated wires of various modi

fi

cations (more than

41 thousand km or 0.9% of the total conductors' length) and bare

conductors (less than 3 thousand km or less than 0.1% of the total

conductors' length) are among these conductors. In addition,

Russian modern power grid is characterized by physical deteriora-

tion and obsolescence of equipment. As a result, low energy ef

fi

-

ciency of power facilities takes place. The most important indica-

tor of power system ef

fi

ciency is the level of energy losses. With

the growing power losses in electrical networks, the number of

urgent problems increases. Reconstruction and technical re-equip-

ment of electrical networks, application of advanced technical

developments in design solutions, implementation of modern tech-

nologies and materials increasing reliability, durability and main-

tainability of power transmission lines are among these problems.

Fokin V.A.,

Director General of

"Energoservis", LLC

Timashova L.V.,

Ph.D., Principal researcher of

the Department for Supporting

Scientifi c and Technical Council

and Scientifi c and Technical

Information, "R&D Center "FGC

UES", JSC

Merzlyakov A.S.,

Head of the Center for

Composite Materials and

Superconductivity, "R&D Center

"FGC UES", JSC

Gurevich L.M.,

D.Sc., Head of the Department

of Materials Science and

Composite Materials, VSTU

Kuryanov V.N.,

Ph.D., Head of Power and

Electrical Engineering

Department, National Research

University "Moscow Power

Engineering Institute"

Nazarov I.A.,

Head of the Substation

Department of the Center

for Reliability and Asset

Management, "R&D Center

"FGC UES", JSC

INTRODUCTION

As of today, fi nding the ways for improving pow-

er grid energy effi ciency is a pressing issue. One

of the ways is the use of innovative conductors

with better characteristics than steel-aluminum

conductors. Increased transmission capacity,

mechanical strength, resistance to high tem-

peratures and resistance to aging and aggres-

sive ambience are among these characteristics.

Power losses optimization in electrical net-

works requires accelerated implementation of

the following activities:

– upgrading power grid equipment and imple-

mentation of new energy-saving technolo-

gies;

– conducting research, design and develop-

ment works related to calculations, analysis,

rationing and reduction of power losses in

electrical networks.

The paper systematizes studies carried out

in the framework of the project for developing

high-temperature and high-strength conductors

according to the relevant Agreement with PJSC

"Rosseti". The task of the studies was to con-

fi rm the possibility of solving the basic problems

of overhead lines construction and operation

through the joint use of ASHT/ASHS conduc-

tors together with overhead ground wires, when

keeping cost at a level of steel-aluminum con-

ductors. The results are shown in table 1 and

described in this paper.

o

v

e

r

h

e

a

d

t

r

a

n

s

m

is

s

io

n

l

in

e

s

overhead transmission lines

3

1

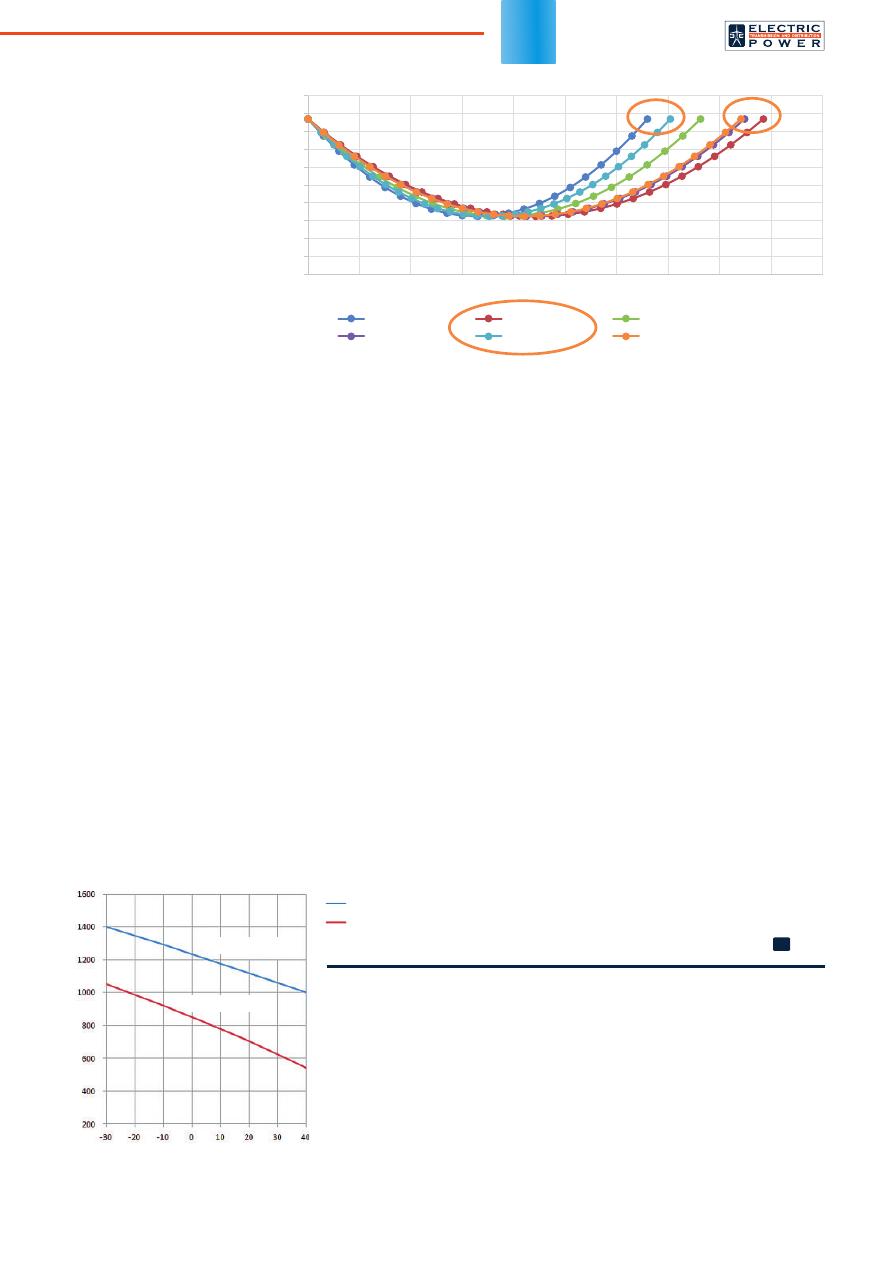

RESEARCH OF CORONA DISCHARGE OCCURRENCE AS A FUNCTION OF VOLTAGE

An important point when using conductors with less di-

ameter is the risk of corona losses and noise level en-

hancement. "R&D Center "FGC UES", JSC

and then VDE (Verband der Elektrotechnik,

Elektronik und Informationstechnik) con-

ducted four studies for testing this problem.

At the fi rst stage, two conductors of the same

diameter (18.8 mm) were taken for comparing

and studying corona discharge. In total, four

conductors were used within the experiment

(Table 2). The tests were carried out in ac-

cordance with IEC 61284 recommendations.

Based on comparative tests results ob-

tained at "FGC UES" R&D Center, it was es-

tablished that ASHS 197/55 conductor manu-

factured by "Energoservis", LLC has corona

discharge voltage (142.2 kV) by 5.7% higher

than ACSR 185/29 conductor (134.5 kV) with

the same diameter (18.8 mm).

Similar tests were carried

out for ASHS 216/33 and ACSR

240/32 conductors with diff erent

diameters. Based on compara-

tive tests results ACSR 240/32

conductor (21.6 mm in dia meter)

and ASHS 216/33 conductor

(18.5 mm in diameter) have

the same corona discharge

voltage. However, continuous

permissible current of the con-

ductors being compared diff ers signifi cantly (510 A for

ACSR 240/32 conductor, 689 A for ASHS 216/33 con-

ACSR150/19

ACSR185/29

ASHS197/55

ACSR240/32

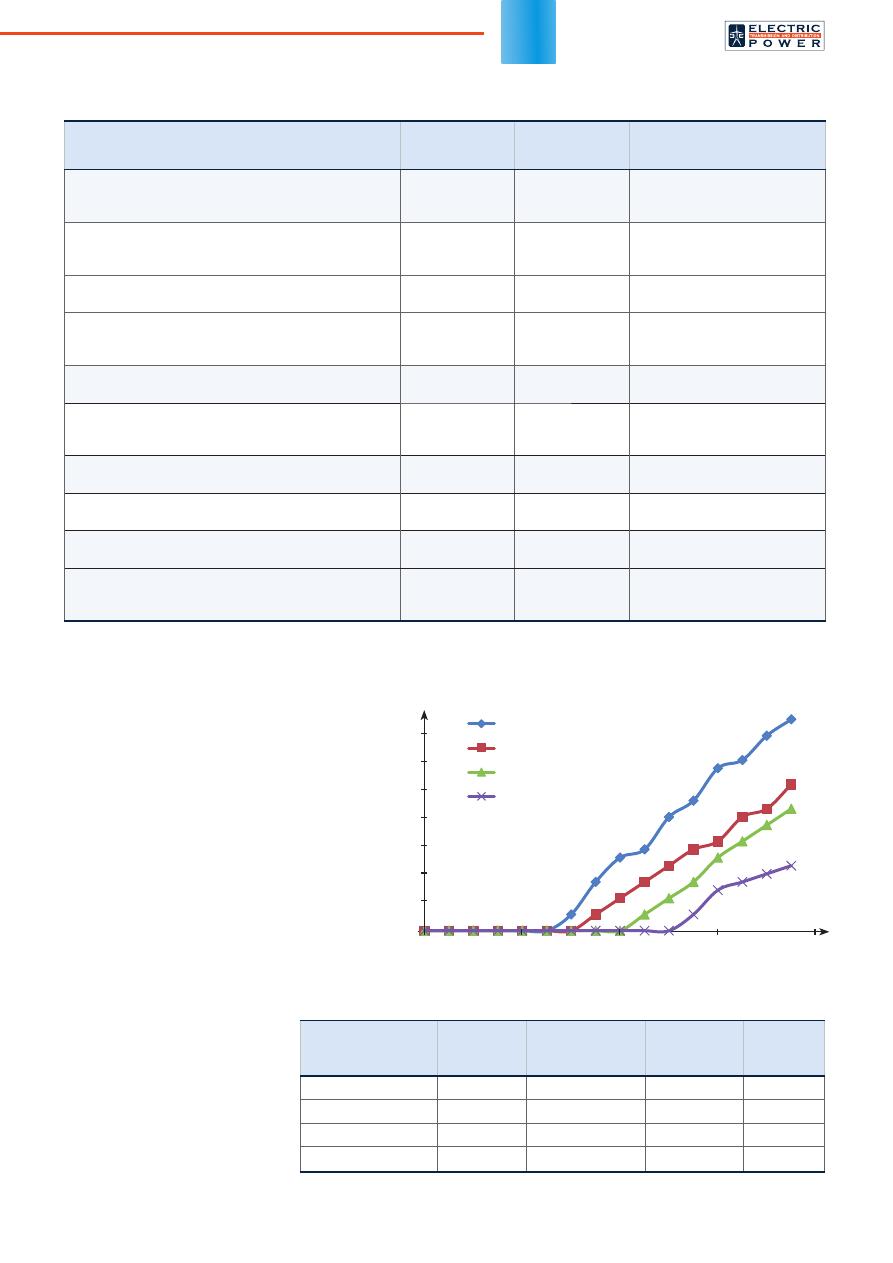

Table 1. Possibilities of solving the main problems of overhead lines

construction and operation through the joint use of ASHS / ASHT conductors

Problem

Solution

based on ACSR

application

Solution based

on ASHS / ASHT

application

Confi rmation

Reducing corona losses and noise level, without

increasing conductor’s diameter

–

+

Experimental confi rmation of

"R&D Center "FGC UES", JSC

and VDE (Germany)

Increasing lightning protection and resistance to short-

circuit currents

–

+

Experimental confi rmation of

"R&D Center "FGC UES", JSC

and VDE (Germany)

Signifi cant reduction of elongation in operation

–

+

Experimental confi rmation of

"R&D Center "FGC UES", JSC

Reducing vibration, galloping and oscillations self-

damping, while keeping conductor diameter

–

+

Experimental and computa-

tional confi rmation of VSTU,

JSC "VNIIZHT" and MPEI

Increasing span length and (or) sags, without increas-

ing conductor’s diameter

–

+

Design solutions

Replacing the conductor on the existing transmission

poles, decreasing the load on all elements of overhead

line and (or) increasing its transmission capacity

–

+

Design solutions

Decreasing wind pressure while keeping conductor

diameter

–

+

Computational confi rmation of

VSTU and MPEI

Replacing the conductor in the ring networks and

decreasing conductor diameter

–

+

Design solutions

Reduction of icing, while keeping conductor diameter

–

+

Computational confi rmation of

VSTU and MPEI

Keeping transmission capacity in areas with high air

temperatures and solar activity, without increasing

conductor’s diameter

–

+

Design solutions and compu-

tational confi rmation of VSTU

and MPEI

Table 2. Technical data of the tested conductors

Conductor model

Conductor

diameter

(external), mm

Number of alumi-

num wires in the

conductor, pcs

Diameter of

outer layer

wires, mm

Continuous

permissible

current

ACSR 150/19

16.8

24

2.8

450

ACSR 185/29

18.8

26

2.98

510

ASHS/ASHT 197/55

18.8

28

3.45

561/943*

ACSR 240/32

21.6

24

3.6

605

* t

max

= 70 °C for high-strength steel-aluminum conductors and t

max

= 150 °C for high temperature

steel-aluminum conductors.

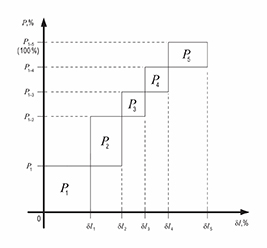

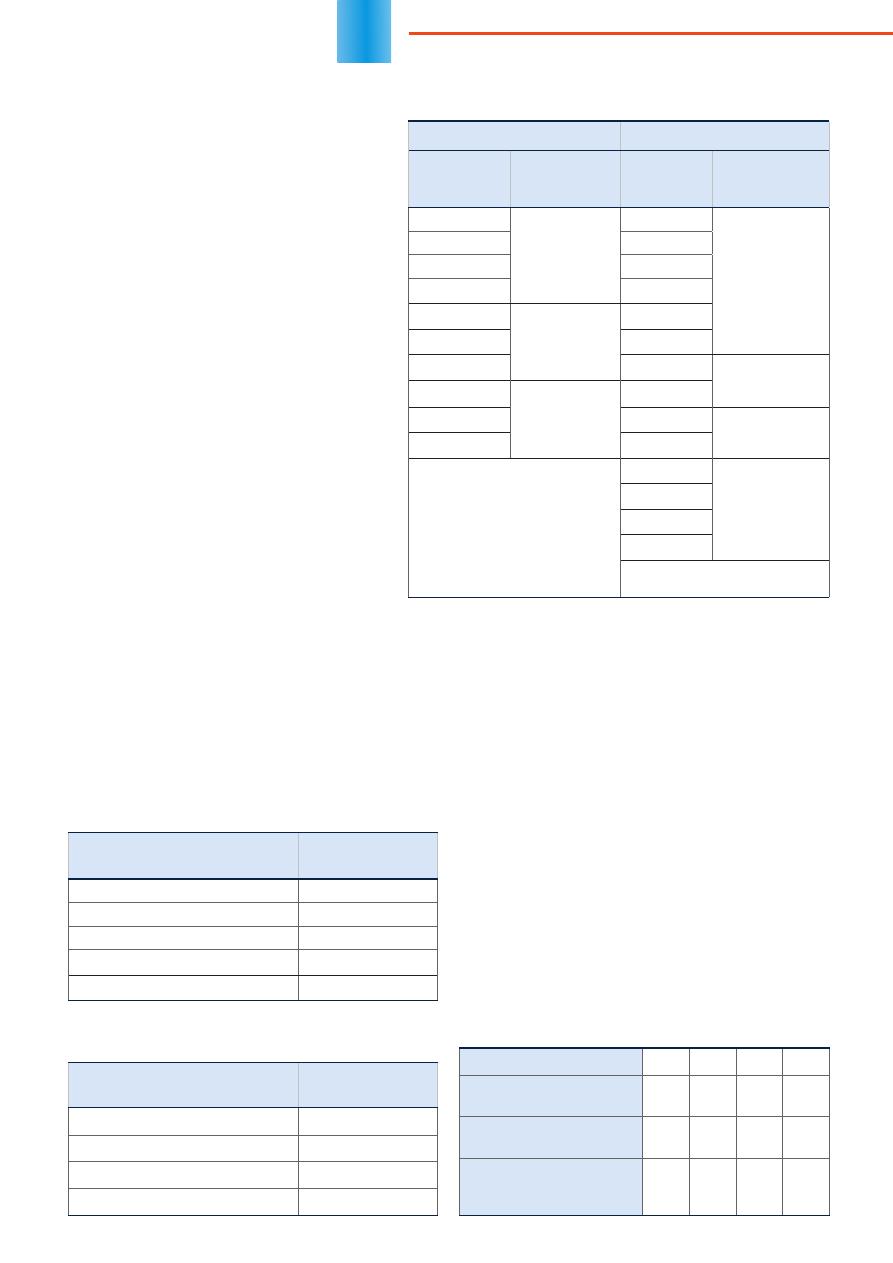

Fig. 1. Dependence of corona discharge points number on voltage

Corona discharge points number

, pcs

Voltage, kV

100

160

180

120

140

30

25

20

15

10

5

0

24th World Energy Congress

Special issue, September 2019

32

ductor (t = 70 °C), and 1040 A for ASHT 216/33

conductor (t = 150 °C)).

The test voltage for inspecting visible corona

on 220 kV overhead lines was determined by

FGH Engineering & Test GmbH laboratory as

167.7 kV (phase voltage). The test voltage of

"R&D Center "FGC UES", JSC laboratory was

160.0 kV (phase voltage).

The test procedure in both laboratories was

identical. Voltage levels and registered results

when testing visible corona are shown in Table 3.

The tests of new ASHT 216/33-1 high-tem-

perature conductor for visible corona inception

were carried out in "FGC UES" R&D Center na-

tional testing laboratory and FGH Engineering &

Test GmbH German testing laboratory. The tests

were performed according to IEC 61284:1998

method and produced similar results for corona

ignition voltage and streamer inception of coro-

na discharge.

The diff erences in the results occur due to

the conditions of conductor samples when test-

ing. Conductor samples were taken directly from

the drum when testing in FGH Engineering & Test

GmbH laboratory. As to the tests of "FGC UES"

R&D Center laboratory, the surface of conduc-

tor samples was additionally cleaned of dirt and

small defects (related to the transportation and

unwinding) that could cause corona discharge.

It was done for studying immunity of new ASHT

19.6-216/33-1 conductors to corona discharge inception.

According to the tests results obtained by the labora-

tories, it was determined that streamer inception of co-

rona discharge for ASHT 19.6-216/33-1 conductor is at

the level of 139.7-150 kV (phase voltage). Based on co-

rona discharge level, this conductor is recommended for

use in domestic and foreign 110, 115, 138 and 150 kV

electrical networks (in some cases the conductor can be

used up to 220 kV).

The calculated specifi c corona losses in good weath-

er are presented in Tables 4, 5. Table 6 gives the aver-

age characteristics of overhead transmission lines in

Russia.

ASHS conductors have advantages in terms of

smaller corona losses in comparison with ACSR con-

ductors of the same diameter. Also, ASHS conductors

have comparable corona losses in regard to ACSR con-

ductors with larger diameter and similar electrical and

mechanical characteristics.

STUDY OF WIND PRESSURE

The direct infl uence of wind on overhead lines opera-

tion is its pressure on the conductors, ground wires and

poles. In addition, wind increases conductors' tension

through creating a transverse load. Additional bending

forces on power line poles also appear. Wind pressure

can cause breakage and fall of the poles with the pull out

of bad fi xed foundations. The results given below proves

the necessity of replacing ACSR conductors with ASHS/

ASHT ones on obsolete overhead lines.

Table 3. Results of visible corona discharge registration

for ASHT-216 / 33-1 conductor

FGH Engineering & Test GmbH "R&D Center "FGC UES", JSC

Test

voltage, kV

Presence of

visible corona

discharge

Test

voltage, kV

Presence of

visible corona

discharge

41.9

Absence of

visible corona

discharge

100.0

Absence of

visible corona

discharge

55.9

105.0

70.0

110.0

83.8

115.0

97.8

Corona ignition

voltage

120.0

111.8

125.0

125.7

130.0

Scant glow of

isolated corona

discharge points

139.7

Streamer incep-

tion of corona

discharge

135.0

153.7

140.0

Stable ignition of

corona discharge

167.7

Increment — 10% of rated test

voltage 167.7 kV (phase voltage)

150.0

Streamer

inception

of corona

discharge

155.0

160.0

165.0

Increment — 5 kV of rated test

voltage 167.7 kV (phase voltage)

Table 4. Calculated specifi c corona losses in good weather

(220 kV overhead line)

Phase construction (conductor

model; conductor diameter)

Annual average

losses change

ACSR 240/32, Ø 21.6 mm

+ 26.67%

ACSR 300/39, Ø 24.0 mm

0.00%

ACSR 330/43, Ø 25.2 mm

–13.33%

ASHS 317/47,

Ø 22.3 mm

–13.33%

ASHS 295/44,

Ø 21.5 mm

–6.67%

Table 5. Calculated specifi c corona losses in good weather

(330 kV overhead line with split phase

consisting of 2 conductors with 40 cm spacing)

Phase construction (conductor

model; conductor diameter)

Annual average

losses change

2 × ACSR 300/39, Ø 24.0 mm

+ 18.52%

2 × ACSR 400/51, Ø 27.5 mm

0.00%

2 × ASHS 317/47,

Ø 22.3 mm

–7.41%

2 × ASHS 295/44,

Ø 21.5 mm

+ 3.70%

Table 6. Average characteristics of overhead lines in Russia

Voltage. kV

220

330

500

750

Average length of over-

head line. km

59

88

187

250

Average diameter of

ACSR conductor. mm

25.6

25.6

27.4

26.1

Possible ASHT / ASHS

conductor diameter in

terms of corona discharge

22.4

22.4

24.5

24

OVERHEAD

TRA

N

SM

I

SS

I

O

N

L

IN

ES

33

COMSOL Multiphysics software package was used

for simulating airfl ow behavior near the conductors. The

software allowed engineers to solve partial diff erential

equations. Navier-Stokes equation was the model basis:

(

u

·

)

u

=

·

–

Pl

+ (

+

T

)(

u

+ (

u

)

T

) –

2

2

– — (

+

T

) (

u

· )

l

– —

kl

+

F

,

3

3

·

(

u

)

= 0,

(

u

·

)

k

=

·

(

+

T

k

*

) (

k

)

+

P

k

–

0

k

,

(1)

(

u

·

)

=

·

(

+

T

*

) (

k

)

+

a

(

/

k

)

P

k

–

0

2

,

T

=

k

/

,

2

2

P

k

=

T

·

u

: (

u

+ (

u

)

T

) –

—

(

·

u

)

2

– —

k

·

u

,

3

3

where

u

is the air velocity; is the del operator;

is the

air density;

is the dynamic viscosity;

k

is the turbulent

kinetic energy;

is the specifi c dispersion rate;

a

,

*

,

k

*

,

0

,

0

are the coeffi cients of turbulent fl ow,

l

is the

turbulence intensity.

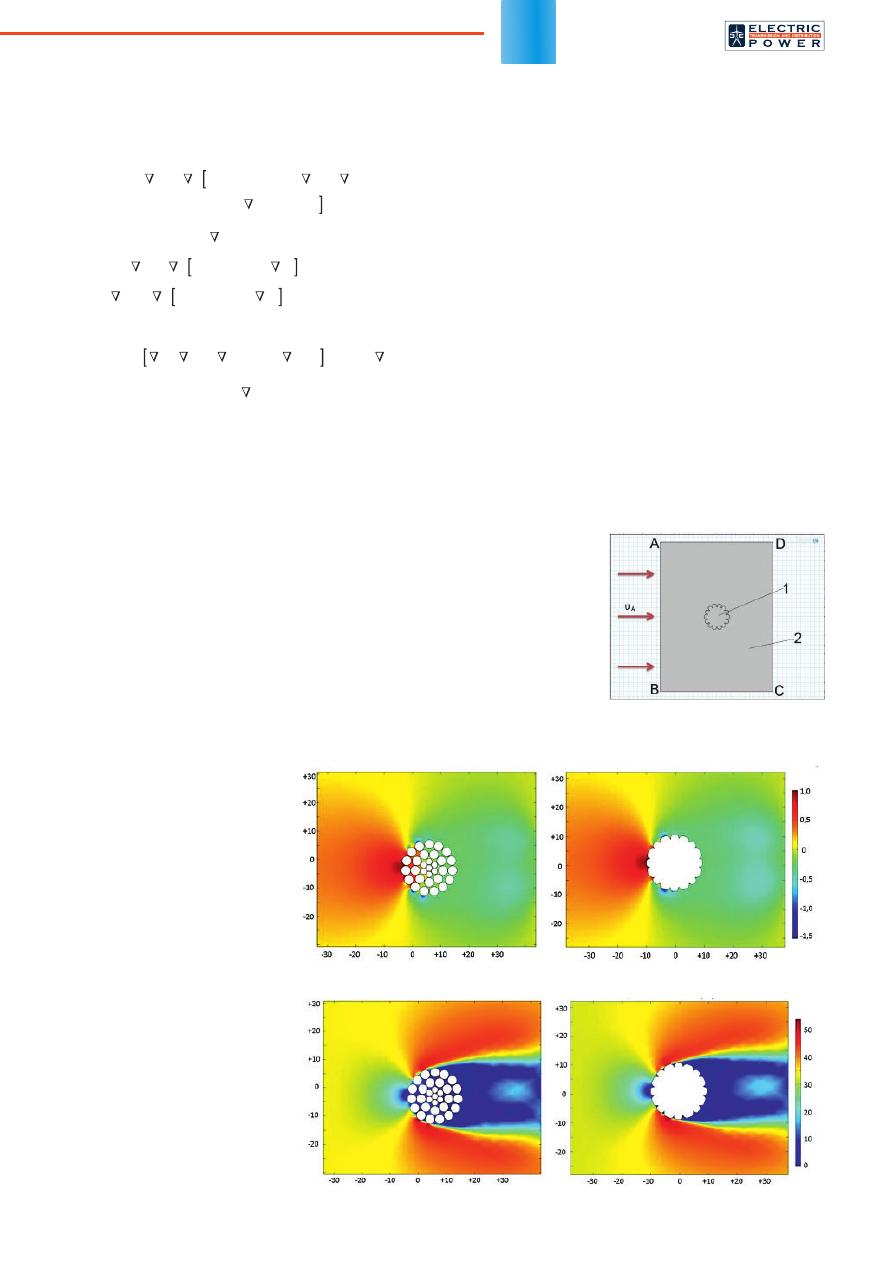

The two-dimensional model was used to assess the

wind impact on conductors with diff erent cross-sectional

shapes. The model’s geometry is shown in Figure 2.

The following boundary conditions were chosen:

– wind speed direction is perpendicular to AB:

AB

=

0

;

(2)

– pressure equals zero on BC, CD and AD faces:

p

= 0 ;

(3)

– the boundaries of conductor’s cross section are non-

deformable walls.

The simulation was carried out at diff erent values of

AB

speed, which are typical for I, III and special wind

zones according to 7th edition of Electrical Installations

Code [1].

The wind load acting on the

conductor across the center

was calculated as the sum of

pressure X-components:

F

=

∫

n

·

P dl

,

(4)

where

P

is pressure,

n

is the unit

vector along the

X

-axis.

The interactions of wind and

conductors depending on wind

speed and type of conductors'

cross-section have been com-

pared. The following conductors

with similar diameters have been

used for comparison: ASHS

128/37 and ACSR 120/19; ASHS

230/32 and ACSR 240/34; ASHS

277/79 and ACSR 240/56 (the

cross-section area of aluminum

and steel in mm

2

represent in

the numerator and denomina-

tor respectively). The calculated

wind load diff ers from

P

H

W

, stan-

dard wind load on conductors

and ground wires, determined

according to 7th edition of Elec-

trical Installations Code. The diff erence takes place due

to ignoring the following facts: wind pressure change at

various heights depending on terrain, the infl uence of

span length on the wind load, wind pressure nonunifor-

mity along overhead line span. The used approach allows

engineers to determine clearly the contribution of conduc-

tor’s contour to the change of wind load.

The view of conductors' contour after crimping was

obtained by modeling steel-aluminum conductor plastic

deformation process in the Abaqus/Explicit module of

the SIMULIA/Abaqus software (Abaqus, Inc., USA). For

all ASHS conductors aluminum wires of outer layer are

tightly adjacent to each other without gaps. It provides

a possibility to simulate the wind impact on a single con-

ductor with one external contour by means of COMSOL

Multiphysics.

The wind pressure acting on the conductors and

air velocity distribution after fl owing around ACSR con-

ductors (according to GOST 839) and ASHS conduc-

tors (according to STO 71915393 – TU 120-2012) with

230 mm

2

aluminum cross section are shown in Figures

3 and 4. A smoother contour and the smaller diameter

of ASHS conductors provide the reduction of pressure

zone in front of the conductor (Figure 3b) and the stag-

nant zone behind

it (Figure 4b). The

maximum pressure

on ASHS conduc-

tors is less by 3.5%,

while the area with

increased pressure

is smaller regarding

to ACSR conduc-

tors. The formation

of several local ar-

eas characterized

by air deceleration

Fig. 2. Geometry of the used model:

1 – conductor cross-section,

2 – air

fl

ow

Fig. 4. Speeds distribution in the air

fl

ow at the wind speed of 25 m/s (the

fi

rst wind

zone): a) ACSR 120/19; b) ASHS 128/37

а)

а)

b)

b)

Fig. 3. Wind pressure acting on the conductors at the wind speed of 60 m/s (the

fi

rst wind

zone): a) ACSR 400/64; b) ASHS 477/66

Wind pressure, kPa

Air speed, m/s

mm

mm

mm

mm

mm

mm

mm

mm

24th World Energy Congress

Special issue, September 2019

34

and reduced pressure is much more visible on the pro-

truding turns of ACSR aluminum wires facing airfl ow front.

As can be seen from the data above, wind load on

ASHS conductors having streamlined design is lower by

33% on the average. Reduction of wind load makes it

possible to reduce the load on power transmission poles

and to mount conductors with greater transmission ca-

pacity on existing poles during capital repairs. Also, the

possibility to reduce the load on all elements of overhead

line when keeping its transmission capacity appears.

REDUCTION OF VIBRATION LOADS

AND OPERATING TENSION

Plastically crimped conductors have a number of advan-

tages, which are usually typical for expensive conduc-

tors from profi led wires. Among these advantages are

vibration loads reducing and oscillations self-damping.

Intensive gust-and-glaze loading of 6-750 kV over-

head power lines is one of the urgent power industry

problems in the countries with relevant weather condi-

tions. Plastically deformed ASHS conductors have al-

most smooth outer surface (close to conductors from

segmented

- and Z-shaped aluminum wires). Due to

this, conductors vibration and galloping as well as ice

coating can be reduced. At the same time, ASHS con-

ductors should have greater torsional rigidity, reduced

galloping probability, increased resistance to vibration,

and self-damping ability even in comparison with con-

ductors from segmented

- and Z-shaped aluminum

wires, because ASHS conductors have developed con-

tact surface of adjacent wires not only inside one layer,

but also between layers [2].

Plastic deformation of conductors not only increases

the mechanical strength signifi cantly, but also several

times reduces elongation during operation (regardless

of the metal). The corresponding tests with products

from diff erent metals (from steel to copper) were carried

out in JSC "VNIIZHT" and "R&D Center "FGC UES",

JSC. Complete study is presented in [3].

INCREASE OF SPAN LENGTH WHEN

CONSTRUCTING NEW FACILITIES

The plastically crimped ASHS and ASHT conductors

allow engineers to increase the distance between

overhead line poles up to 40% of the standard span

(in the absence of restrictions related to line route).

It is an urgent task when constructing new overhead

lines. For example, the comparative analysis of the

span length for ASHS 128/37 conductor mounted on

110 kV overhead line and ACSR 120/27, TACSR 120,

ACSR 120/19 conductors with the same cross-section

and dia meters has been fulfi lled. Because of ASHS

128/37 conductors application the span length can be in-

creased from 212 to 294 m compared with ACSR 120/27

conductor. ASHS 128/37 conductor has a higher content

of steel (the ratio between aluminum and steel cross-sec-

tion area is 3.45 for ASHS 128/37 conductor and 4.3 for

ACSR 120/27 conductor), an equal diameter (15.2 mm),

and increased transmission capacity (by 8% higher).

An example of ASHS/ASHT conductors application

effi ciency is the initial project of 150 kV Murmanskaya

overhead line (Table 8 and Figure 5). ASHS 258/73 con-

ductor is the most eff ective option when constructing

new overhead line. In its turn, ASHS 216/33 conductor

is the optimal option when reconstructing overhead line

(replacing conductors on existing power transmission

poles). 220 kV overhead line project developed by "FGC

UES" R&D Center is also an illustrative example.

Proper use of developed conductors in combination

with ground wires (TU 062-2008) or fi ber-optic ground

wires (TU 113-2013) for new construction and recon-

struction of 35-750 kV overhead lines can signifi cantly

increase their transmission capacity, reduce capital and

operating costs and enhance reliability when exposing

entire range of climatic loads.

SUPPORTING TRANSMISSION CAPACITY

IN THE REGIONS WITH HIGH AMBIENT

TEMPERATURE WHEN KEEPING THE COST

Due to its design features, ASHT high-temperature con-

ductor is cheaper by several times regarding to import-

ed analogs with a long-term permissible temperature of

150 °C. Characteristics and features of ASHT conductor

are confi rmed by the Russian-German tests.

According to existing Electrical Installations Code,

permissible current is determined taking into account

the highest conductor’s

temperature (70 °C).

The calculation of the

limit currents at the tem-

pe ra tures below 45 °C

can be produced ignor-

ing the infl uence of solar

radiation. Absorbed solar

radiation in the middle

latitudes can heat con-

ductors by 2-3 °C (for

conductors operating in

the temperature range of

60-70 °C and above).

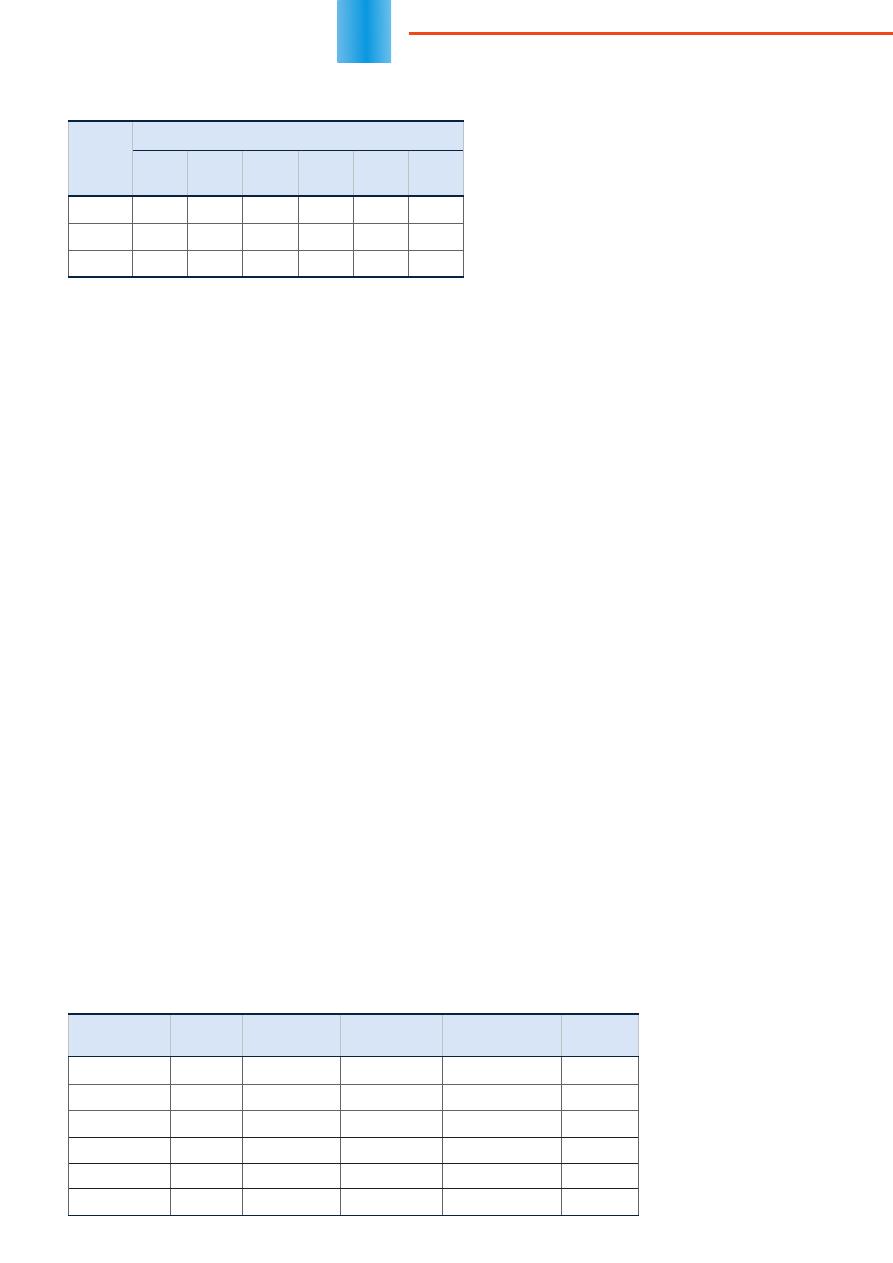

Table 7. Wind load for conductors with

diff erent cross-section contour depending on airfl ow speed

Airfl ow

speed

v

AB

, m/s

Wind load acting on conductors, N / m

ASHS

128/37

ACSR

120/19

ASHS

216/32

ACSR

240/34

ASHS

277/79

ACSR

240/56

25

3.6

4.8

4.9

6.9

5.2

7.0

32

5.9

7.9

7.8

11.4

8.4

11.5

60

20.8

28.5

28.4

41.5

29.8

41.6

Table 8. Indicators of ASHS/ASHT application

on 150 kV Murmanskaya overhead transmission line

Conductor

Breaking

load, kN

Maximum

tension, daN

Conductor

diameter, mm

Weight of con-

ductor (1 km), kg

Span

length, m

ACSR 240/32

75.05

3377.33

21.6

921

330

ASHS 258/73

151.533

6819.13

21.6

1296.5

443

ASHS 295/44

109

4905.05

21.5

1183

382

ASHS 218/63

130.096

5854.44

19.82

1106.7

424

ASHS 216/33

81.5

3667.51

18.5

855

352

ASHS 214/61

126.672

5700.33

19.6

1080.9

421

ВОЗДУШНЫЕ

ЛИНИИ

OVERHEAD

TRA

N

SM

I

SS

I

O

N

L

IN

ES

35

ASHT conductor is cap -

able to withstand a greater

load under equal environ-

mental conditions in compar-

ison with ACSR conductor.

The diff erence in permis-

sible load for the compared

conductors is 5%. The tem-

perature of ASHT conductor

is lower comparing to ACSR

conductor, when increasing

current load. The tempera-

ture diff erence is especially

noticeable at high currents

(around 5-7%).

It should be noted that,

according to the regulatory

documentation, standard conductors are allowed to oper-

ate when their temperature is up to 90 °C. The permis-

sible temperature for ASHT conductors is 150 °C.

Figure 6 represents the dependence of permis-

sible current load on the air temperature (wind speed is

1.2 m/s) for ACSR and ASHT conductors in conditions of

the maximum operating temperature of 80 °C and 150 °C,

respectively. Continuous permissible current for high-tem-

perature conductor is 30-35% higher than the value for

standard conductor of the same diameter. Thus, innova-

tive conductor can be used when signifi cant enhance of

transmission capacity without increasing the cross-sec-

tion, is required. Also the innovative conductor can be im-

plemented in the areas with high ambient temperatures.

CONCLUSIONS

1. Conducted studies have shown the following:

– ASHT conductors' application in electrical grid is the

eff ective solution (the data on the ultimate loads, the

reduction of heat release and magnetization of the

conductors in operation have been obtained);

– ASHS conductors have corona discharge voltage

higher, than ACSR conductors with the same diameter;

– the relative decrease of ASHT conductor magnetiza-

tion in comparison with ACSR conductor is 3-10%.

2. The obtained results show that innovative ASHT

conductors' application is justifi ed when signifi cant

increase of transmission capacity without increas-

ing the cross-section is required. Also, the innovative

conductor can be used in the areas with high ambient

temperatures.

3. Based on multivariate comparative analysis, the

comparable cost of ACSR and ASHT/ASHS conduc-

tors does not increase costs of overhead lines con-

struction and reconstruction.

4. The application of ASHT conductors provides corona

losses decrease and span length enhancement. It

reduces the total cost of overhead lines and ensures

economic eff ect when reconstructing electrical net-

works.

5. Design features of ASHS/ASHT conductors reduce

the load on all elements of overhead lines when re-

placing conductors on existing power transmission

poles. Construction of new overhead transmission

lines is necessary, taking into account that exist-

ing overhead lines operate more than 25-40 years

and are obsolete. The discounted payback period

for replacing standard conductors does not exceed

5 years per 1 km of 110 kV electrical network located

in the Volgograd region.

6. The applied technology of plastic deformation pro-

vides a number of advantages noted by PJSC "Ros-

seti" Technical Council:

– increase in the fi ll factor of the conductor up to 92-97%;

– reduction of aerodynamic load (by 20-35%) and

oscillations self-damping;

– reduction of icing (by 25-40%) and lowering of oper-

ating conductor elongation in several times.

Р

Fig. 5. Calculated spans for 150 kV Murmanskaya overhead transmission line

0

2

4

6

8

10

12

14

16

18

20

0

50

100

150

200

250

300

350

400

450

500

Conductor’ suspension height, m

Span length, m

ACSR 240/32

ASHS 258/73

ASHS 295/44

ASHS 218/63

ASHS 216/33

ASHS 214/61

Fig. 6. Dependence of current load

on ambient temperature for ACSR and

ASHS conductors with the same

diameter at the wind speed of 1.2 m/s

Ambient temperature, °C

I

per

, А

T

max

= 150 °С

ASHS 258/73

ACSR 240/39

T

max

= 80 °С

REFERENCES

1. Gurevich L.M., Danenko V.F., Pronichev D.V., Trunov M.D. Modeling of electro-

magnetic losses in various steel-aluminum conductors.

ELEKTROENERGIYa.

Peredacha i raspredelenie

[ELECTRIC POWER. Transmission and Distribution],

2014, no. 5(26), pp. 68-71. (in Russian)

2. Loparev V.V., Obraztsov Yu.V. On the features of modern conductors for overhead

power lines.

Kabeli i provoda

[Cables and Wires], 2014, no. 6(349), pp. 9-15. (in

Russian)

3. Kuryanov V.N., Sultanov M.M., Fokin V.A., Timashova L.V. Innovative high-ef-

fective conductors for power lines.

Energiya edinoy seti

[Energy of Unifi ed Grid],

2016, no. 4(27), pp. 70-78. (in Russian)

"Energoservis", LLC

rsppvolga@mail.ru www.energoservise.com

24th World Energy Congress

Special issue, September 2019

Оригинал статьи: Efficiency of Implementing Domestic Innovative High-strength and High-temperature Steel-Aluminum Сonductors

PJSC «Rosseti» maintains 44 thousand km of new conductor types or 1% of the total conductors’ length (4.5 million km). Self-supporting insulated wires of various modifications (more than 41 thousand km or 0.9% of the total conductors’ length) and bare conductors (less than 3 thousand km or less than 0.1% of the total conductors’ length) are among these conductors. In addition, Russian modern power grid is characterized by physical deterioration and obsolescence of equipment. As a result, low energy efficiency of power facilities takes place. The most important indicator of power system efficiency is the level of energy losses. With the growing power losses in electrical networks, the number of urgent problems increases. Reconstruction and technical re-equipment of electrical networks, application of advanced technical developments in design solutions, implementation of modern technologies and materials increasing reliability, durability and maintainability of power transmission lines are among these problems.