The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

3 - 6 J U N E 2 0 1 9

MADRID, SPAIN

The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

3 - 6 J U N E 2 0 1 9

MADRID, SPAIN

30

Durable Reinforced Concrete

Power Transmission Poles Made

of Nanomodifi ed Concrete — the Future

of Digital Distribution Networks

Valentina SOLOVIOVA,

D.Sc., Prof. of Emperor Alexander I

St.-Petersburg State Transport University

Peter ROMANOV,

Ph.D, Ch.Eng. Scientifi c Research

Laboratory of Electrical Grid Construction

Liubov KACHANOVSKAYA,

PhD, Нead of Scientifi c Research

Laboratory of Electrical Grid Construction

Sergey KASATKIN,

Eng. Scientifi c Research Laboratory

of Electrical Grid Construction

Tatyana SBOYCHAKOVA,

Eng. Scientifi c Research Laboratory

of Electrical Grid Construction

Improving the reliability and durability of reinforced concrete poles for overhead transmis-

sion lines is a direct way to reduce costs when constructing and operating energy facilities.

Modern chemical additives can signi

fi

cantly affect the structure of concrete and improve its

operational properties: strength, density, freeze-thaw, water and corrosion resistance. Iden-

ti

fi

cation and digital certi

fi

cation of power transmission poles with new properties is a guar-

antee of their sustained quality. The paper presents data on the industrial production of poles

from nanomodi

fi

ed concrete. Also, the paper considers directions for further work on creating

the uni

fi

ed series of 0.4 and 6-10 kV reinforced concrete power transmission poles character-

ized by high durability for digital distribution electrical networks.

A

s of today, the length of overhead transmission lines with

up to 20 kV voltage exceeds 2 million km in Russia. Tra-

ditionally these overhead lines are performed on vibrated

concrete poles.

The development of economy, new technologies and popula-

tion needs requires upgrading distribution networks in regards

to increasing their length and functionality (Figure 1). New types

of conductors are used for increasing transmission capacity. Ap-

plication of additional fi ber-optic links is required for establishing

communication channels. Growing needs lead to load increase

of power transmission poles and enhanced requirements for

their load-carrying ability. Telecommunications networks require

increased reliability coeffi cient for power transmission poles

(1.5 times more for ice loading). In addition, the poles of distribu-

tion networks are often constructed along highways. As a result,

they are exposed to the aggressive infl uence of deicing products

in winter.

Thus, there is a need to increase such operational character-

istics of vibrated reinforced concrete poles as load-carrying ability

and crack, freeze-thaw, water and corrosion resistance.

The solution of this task is achieved through the rational use of

the internal reserves of the cement-containing system — applica-

tion of new activating chemical additives.

A complex additive for concrete consisting of several compo-

nents of diff erent nature and specifi cally SiO

2

·nH

2

O nanodisper-

sions was developed at the Department of Engineering Chemistry

and Natural Science of St. Petersburg State Transport University

(PGUPS). Presented nanodispersions promote the formation of

hardly soluble compounds that are more resistant to the aggres-

sive eff ects of salts and have a positive eff ect on the corrosion

resistance of concrete.

Besides, the formation of an additional amount of hydrate joints

with a needle-shaped structure is capable to provide micro rein-

forcing of concrete, its compaction, and as a result, increasing its

strength, crack resistance and durability.

It is obtained that eff ective chemical activation of nanomodi-

fi ed concrete signifi cantly heats the curing mass. It has a positive

eff ect on hydration processes and allows engineers to reduce sig-

nifi cantly the temperature in the curing chambers and to abandon

their heating at all in summer.

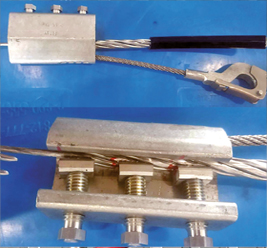

Fig. 1. 10 kV power transmission poles for

overhead-underground transition

OVERHEAD

TRA

N

SM

I

SS

I

O

N

L

IN

ES

3

1

The developed complex additive was tested at the

factories of "PO "Energozhelezobetonivest", LLC during

the manufacture of SV95-3s reinforced concrete poles

with B30 W6 F

1

200 design parameters of concrete. Stan-

dard plant products from concrete mixture containing only

polycarboxylate-based additives were taken as control

samples. The developed complex additive is comparable

in cost to the additive used in the plant. The additives dos-

age was kept at the same level. The poles were tested

according to state standard 8829-94 (GOST 8829-94) for

assessing their strength, hardness and crack resistance.

Such physico-mechanical parameters of concrete as the

compressive strength (after curing, at the age of 7 and

28 days), water and frost resistance were under control.

The test results of reinforced concrete poles showed

that products with the developed chemical additive had

lower values of such indicators as the number and aver-

age width of cracks and poles defl ection.

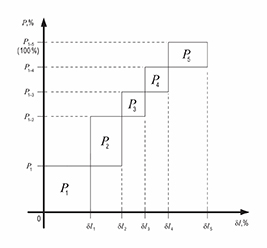

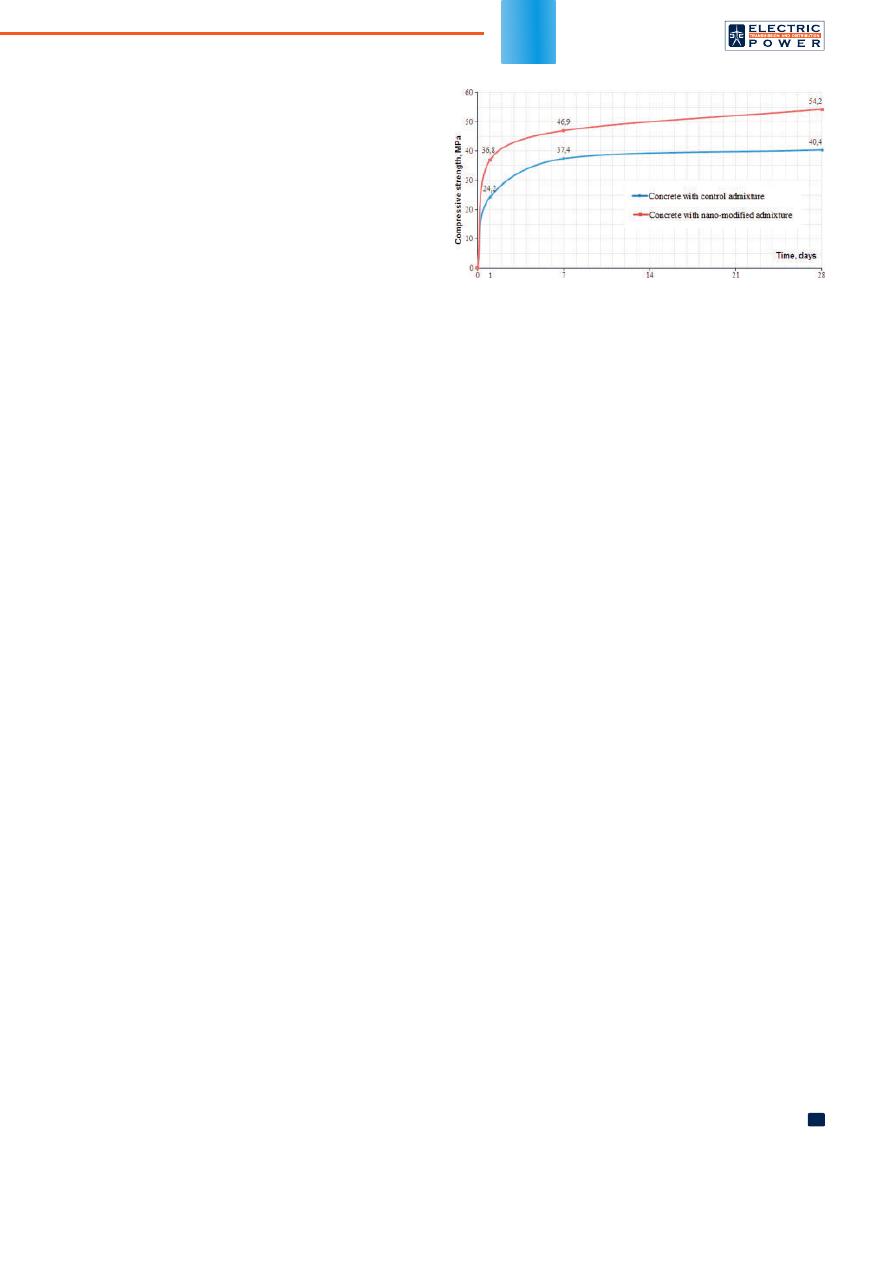

Samples of nanomodifi ed concrete with developed

additive diff ered in high strength. The kinetics of concrete

strength development when curing at a temperature of

60 °C (reduced temperature relative to usual values) is

presented in Figure 2.

The strength of nanomodifi ed concrete in compres-

sion at the age of 28 days exceeded the control values by

34%. It corresponds to class B40 (Figure 2).

Samples of nanomodifi ed concrete diff ered in in-

creased water resistance (twice more), corresponding

to W12 mark. Frost-resistance increased by 2.5 times. It

conforms to F

1

500 mark.

Nano-modifi ed concrete with B30 design class can be

obtained by reducing cement consumption by 30%, while

water resistance increasing by 3 steps to W10 mark, and

frost-resistance double enhancing to F

1

400 mark.

The results indicate the eff ectiveness of developed ad-

ditive for manufacturing concrete products such as poles,

piles, pad and chimney foundations.

As of today, the use of nanomodifi ed concrete at the

plants of "PO "Energozhelezobetonivest", LLC allows en-

gineers to manufacture typical structures of increased du-

rability while maintaining the existing cost.

Signifi cant savings at the construction stage of the

facilities can be achieved by developing new designs of

poles, piles and precast foundation with the use of mod-

ern high-strength and durable concrete and high duty

reinforcement. The list of topics recommended for imple-

mentation within the framework of PJSC "Rosseti" R&D

already includes "Development of unifi ed series of extra

durable reinforced concrete poles for 0.4 and 6-10 kV

overhead transmission lines using nanomodifi ed con-

crete and electronic passport elements". The develop-

ment of reinforced concrete poles with enhanced values

of load-carrying ability will provide an increase of span

length for overhead lines by 20-25% and an economic

eff ect by reducing the number of intermediate poles and

related costs of their construction and maintenance.

Nanomodifi ed concrete application will ensure a lifetime

of reinforced concrete poles over 50 years (in some cases

a lifetime can reach even 100 years). This will signifi cantly

reduce repairing costs.

New power transmission poles will be equipped with

radio-frequency tags (microchips) containing a unique

identifi cation number. This number provides access to the

electronic passport and, hence, to information on poles

life cycle and technical documentation with detailed in-

formation on the released product and its characteristics.

Electronic certifi cation of reinforced concrete poles will

allow engineers to produce products diff erentially and to

supply them on energy facilities taking into account indi-

vidual corrosion protection requirements. Products iden-

tifi cation will allow the customer interested in quality to

choose poles based on their properties. In addition, it will

increase the responsibility of the manufacturer and sup-

plier, ensure stable quality of the products used at the fa-

cilities, and exclude the supply of products mismatching

the claimed characteristics. As a result, there will be no

problems during operation. Information on each product

with reference to specifi c power transmission pole will be

added to the electronic passport of overhead line.

CONCLUSIONS

1. A complex chemical additive for concrete has been

developed. It includes nanosize dispersions, which make

it possible to produce nanomodifi ed concrete character-

ized by high strength, density, freeze-thaw, water and

corrosion resistance. Such concrete provides increased

reliability and durability of structural units.

2. The cost of reinforced concrete products made from

extra durable concrete does not diff er from the cost of

standard structures. At the same time, the use of durable

structures eliminates the need for repairs throughout the

entire service life. This fact has the greatest importance

for foundation structures — piles and pad and chimney

foundations operating in rough soil conditions (there is no

access to these structures during their operation).

3. Early order of existing standard designs using nano-

modifi ed concrete can signifi cantly reduce operating

costs in the future.

4. The development of new unifi ed series of reinforced

concrete poles with increased reliability and durability for

0.4 and 6-10 kV overhead lines will decrease the cost of

transmission lines construction by means of reducing the

number of poles per kilometer. Also, operation costs will

be reduced due to the absence of repairs. A digital elec-

tronic passport will allow engineers to transfer all informa-

tion about the product to the IT system of electrical net-

work for solving the problems of production and technical

management, monitoring and equipment diagnostics.

Р

Fig. 2. Kinetics of concrete strength development

Scientifi c Research Laboratory

of Electrical Grid Construction

Tel.: +7 (911) 285-94-61, +7 (812) 309-39-61

E-mail: t.i.sboychakova@nilkes.ru www.nilkes.ru

The 25th CIRED Session

Special issue, June 2019

Оригинал статьи: Durable Reinforced Concrete Power Transmission Poles Made of Nanomodifi ed Concrete — the Future of Digital Distribution Networks

Improving the reliability and durability of reinforced concrete poles for overhead transmission lines is a direct way to reduce costs when constructing and operating energy facilities. Modern chemical additives can signifi cantly affect the structure of concrete and improve its operational properties: strength, density, freeze-thaw, water and corrosion resistance. Identification and digital certifi cation of power transmission poles with new properties is a guarantee of their sustained quality. The paper presents data on the industrial production of poles from nanomodifi ed concrete. Also, the paper considers directions for further work on creating the unifi ed series of 0.4 and 6-10 kV reinforced concrete power transmission poles characterized by high durability for digital distribution electrical networks.