Оригинал статьи: Diagnostics and Analysis Tools

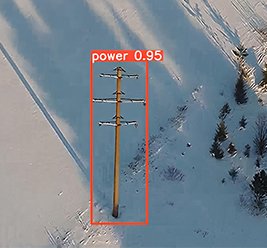

The technical policy of JSC “Russian Grids” (Rosseti) on development of digital substations without permanent operating personnel, improvement of reliability and operation effi ciency of power grid facilities impose strict requirements on all substation automation components and products.