The MAIN JOURNAL for POWER GRID SPECIALISTS in RUSSIA

24

Digital Networks Construction

in ROSSETI Group

Today power engineering development is largely determined by technological break-

throughs, taking place in various economy sectors. Within this framework, electric

power industry task is not only to keep up with constant technology changes and

power consumers requirements, but also to be one step ahead, as global energy

changes with technological paradigm shift is instantly impossible [1].

F

rom a technological view-

point, the main develop-

ment will be directed to-

wards the automation

and control systems in the next

20-30 years. It is impossible with-

out increasing electric networks ob-

servability and manageability.

Electric power engineering

should be improved and be on

par with information technology in

the digital economy. Electric net-

works of the future are digital net-

works [1].

According to ROSSETI Group

de

fi

nition, "Digital network is a set

of electric grid facilities where ef-

fective management key factor is

digital data. The usage of high-

volume data processing and results

analysis allows electric grid com-

panies to improve signi

fi

cantly the

ef

fi

ciency, availability and service

quality for consumers".

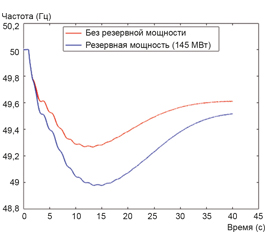

Generation, transmission and

processing of data on electric grid

conditions and electric network

modes in digital form can be depict-

ed in the pyramid form (Figure 1).

The basic level of digitalization

is the primary sensors, directly

reading and transmitting informa-

tion about digital network param-

eters. For 0.4 kV electrical network,

those primary sensors are digital

energy meters (modern smart me-

ters). Currently, digital meters can

perform not only direct functions of

measuring amount of electric pow-

er, but also record various electrical

characteristics required for intelli-

gent digital control of the network.

In addition, the joint use of digital

meters and modern protective de-

vices gives the greatest economic

effect associated with accounting

and minimization of losses and

consumers load managing.

Digitalization of 6 kV and above

electrical networks is achieved

by ensuring observability and

controll ability of facilities and relay

protection and automation devices

with innovative algorithms imple-

mentation. As known, a number

of distribution network substations

are operated without telesignali-

zation and telecontrol at the mo-

Figure 1. Digital network structure

Digital network management systems

Smart metering

Teleautomation

Connection/Cybersecurity

Managed network elements

Digital

data

mana-

gement

Digital

data

gene-

ration

DIGIT

AL

NETWORK

Dmitriy

GVOZDEV,

Chief Engineer,

PJSC ROSSETI

Vladimir

UKOLOV,

Deputy Director of the

Situation and Analytical

Center, PJSC ROSSETI

Dmitriy

KHIZHKIN,

Deputy Head of the

Information Security

Department,

PJSC ROSSETI

Evgeniy

SELEZENEV,

Deputy Head of the

Technical Department,

PJSC ROSSETI

Aleksandr

KARTUSHIN,

Chief Expert,

Technical Solutions

Division, Operational

and Technological

Management Department,

PJSC ROSSETI

Valeriy

KIRILENKOV,

Chief Expert, Division

of Relay Protection

and Automation

Development, Operational

and Technological

Management Department,

PJSC ROSSETI

power grids digit

aliz

a

tion

25

ment. Therefore, such substations

can’t operatively react on changes

of network operating modes. Te-

lemetry and telecommand of dis-

tribution network substations will

ensure controllability within the

shortest possible time and with

minimal reconstruction of the main

equipment. According to ROSSETI

Group viewpoint, the global re-

placement of outdated switching

devices is not required. The main

equipment will be replaced on

a scheduled basis. Renovation will

be coordinated with facility digitali-

zation plans. It is necessary to pro-

vide transmitting and processing

of switching devices status data

in the digital network by means of

telecontrol devices. Switching con-

trol should ensure normal mode

of electrical network. Also, digital

network should provide automatic

remote control instead of mechani-

cal actions conducted by network

operator and substation electri-

cian.

The third digitalization level is

the provision of all power grid facili-

ties and operational staff with reli-

able and safe digital communica-

tions. In addition, this digitalization

level is meant to ensure continuous

and integrated security of informa-

tion systems, telecommunications

networks, software and soft hard-

ware designed for technological

and production equipment monitor-

ing and management.

With the advent of the fourth in-

dustrial revolution, isolation of the

technological network from any

external systems can no longer be

considered as an adequate protec-

tive measure. Digital network re-

quires the interfacing of corporate

and technological automated con-

trol systems and greater freedom

of communication. As a result, the

technological network becomes

more and more similar to the corpo-

rate one. They have the same use

scenario and techniques in ope-

ration. Therefore, the threats to in-

dustrial automated control systems

are similar to the threats of corpo-

rate systems.

At the same time, there is an-

other world trend: the growth of

detectable vulnerabilities in the

software of industrial automation

systems. Computer attacks on in-

dustrial facilities become more so-

phisticated and dangerous.

For ensuring continuous and in-

tegrated security of information in-

frastructure, ROSSETI Group plans

to implement a security strategy

based on automating the detec-

tion and prevention of computer at-

tacks. It is planned to use machine

learning algorithms and heuristic

analysis, as well as technologies

of the fastest possible recovery of

information infrastructure.

Energy entities in ROSSETI

Group have a task to create a se-

curity system for information infra-

structure facilities. The system will

represent typical territorially distrib-

uted complex designed to detect

and prevent computer attacks and

eliminating the consequences of

computer incidents.

ROSSETI Group uses such mo-

dern switching devices as automat-

ic reclosers, circuit breakers and

disconnecting devices with motor

drive to ensure the required level

of power supply reliability, to lo-

cate damaged areas and to restore

post-emergency network scheme.

It should be noted that digital me-

ters with embedded switching de-

vices can be applied as control-

lable elements for 0.4 kV electrical

networks.

The top of digital network is an

automated control system includ-

ing display facilities of network ele-

ments and network management.

The automated system is used for

production assets management

and repair of power grid facilities

based on information on their tech-

nical condition.

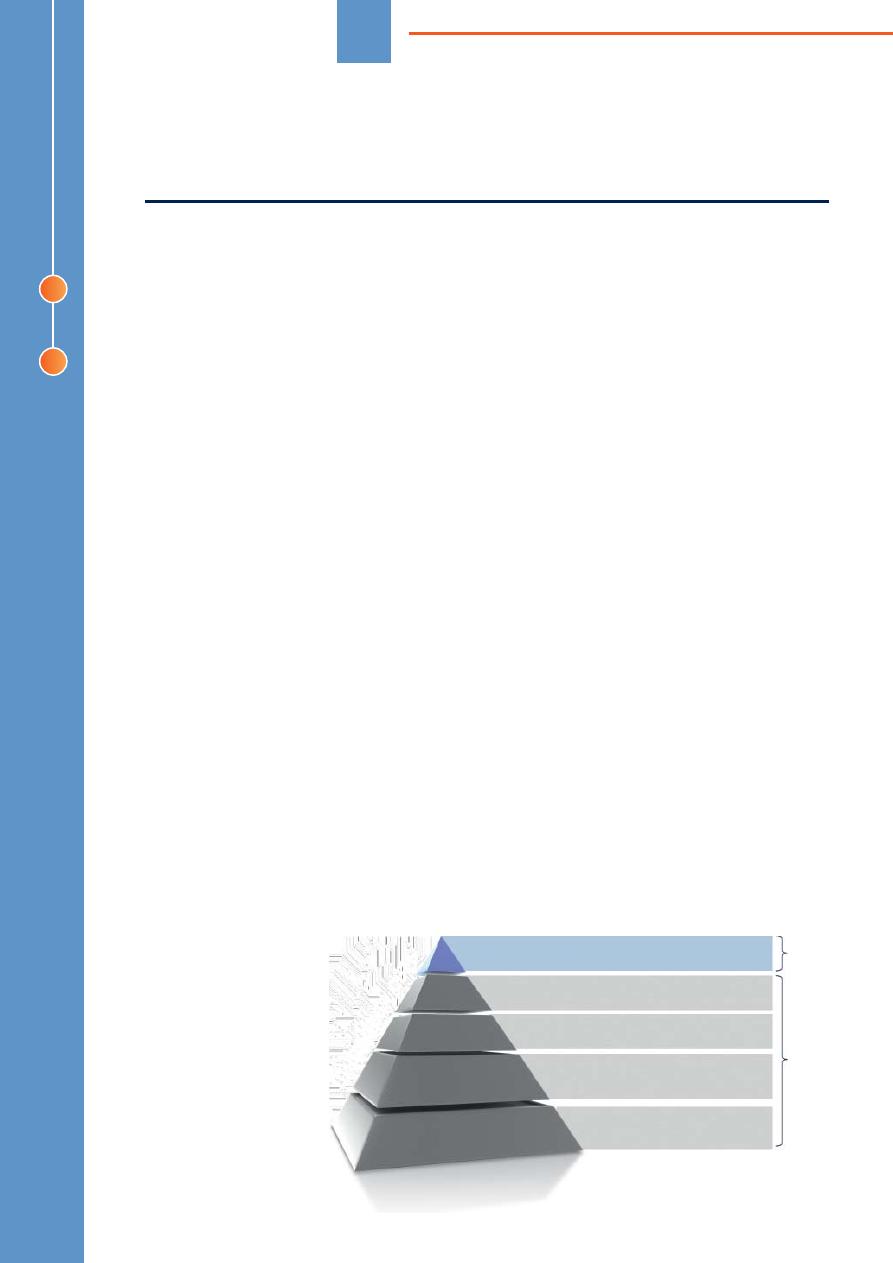

Currently, ROSSETI Group has

implemented a software package

providing the possibility of tran-

sition to a risk-based model of

production assets management

(PAM). The task of the software

is to optimize production program

costs while improving equipment

reliability (Figure 2).

The task is executed using

risk-based asset management

methodo logy including techniques

for assessing main equipment

technical condition, failure probabi-

lity and

fi

nancial consequences

of equipment failure. Important

components of the production as-

sets management system are re-

mote monitoring and diag

nostic

subsystems using BigData tech-

nologies with predictive analy

tics

functions.

PAM application scenario is

implemented for risk-oriented ma-

nagement of information infrastruc-

ture facilities taking into account

facility life cycle, technical main-

tenance organization and critical

software updates installation.

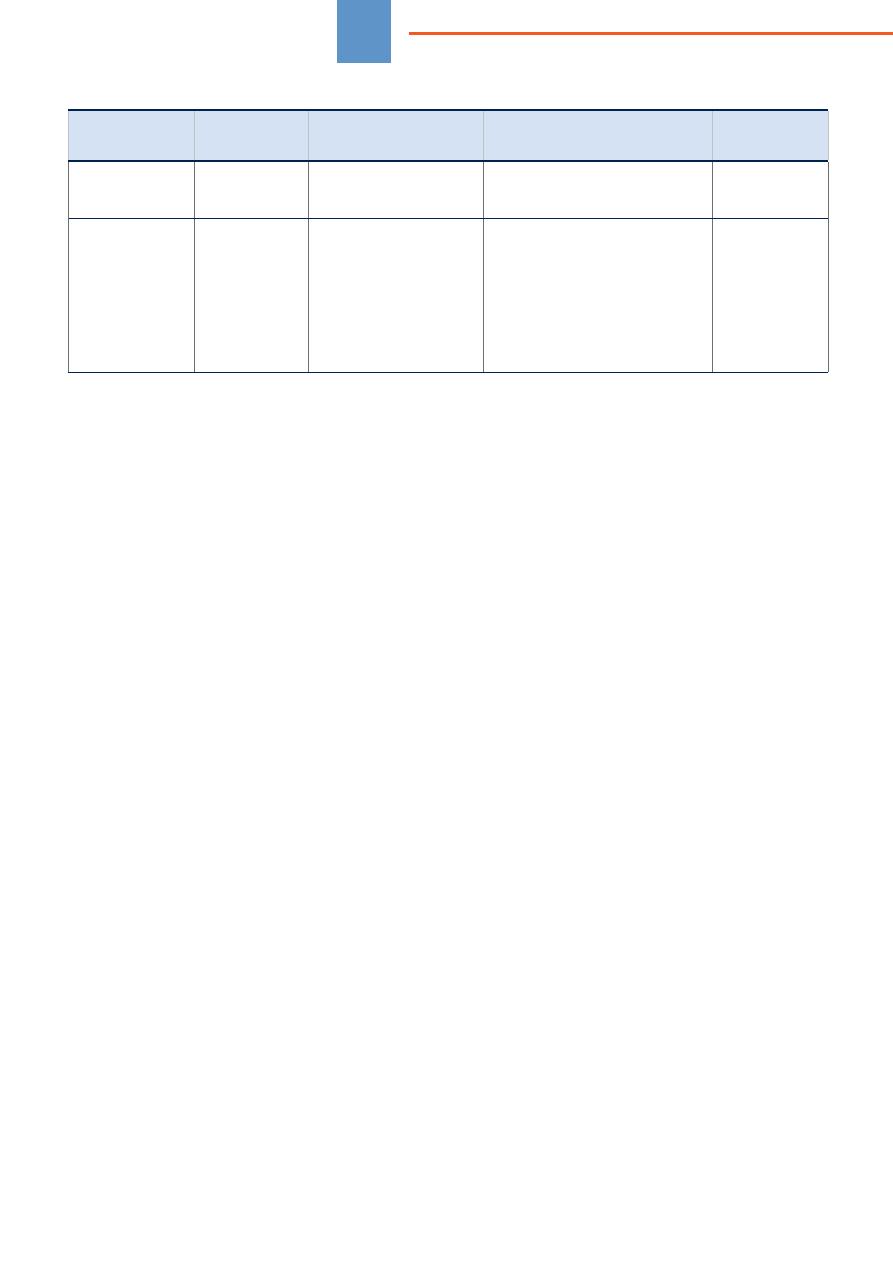

Depending on power grid equip-

ment (Table 1), a different amount of

digital technologies is required. For

the purposes of effective decision-

making on equipment replacement

ROSSETI Group has developed

a matrix of technical solutions, con-

taining the rules for replacement

of various equipment with modern

digital analogs (Table 2).

The implementation of large-

scale power grid equipment up-

dating is planned for several years

and therefore should be conducted

step by step. It will gradually de-

velop hardware architecture, soft-

Figure 2. Existing and targeted relations between costs and reliability

High reliability

when low costs

COSTS

RELIABILITY

INDEXES

High reliability

when high costs

47th CIGRE Session

Special issue, August 2018

26

ware and information support. In

addition, large-scale plans require

signi

fi

cant

fi

nancial costs. It is obvi-

ous, that continuous replacement of

all devices with digital ones will not

provide the necessary economic

effect. By this reasoning ROSSETI

Group has implemented differenti-

ated approach to power grid facili-

ties digitalization:

• The reconstruction is required

for 35 kV and above substations

aged 50 years or more;

• The equipment upgrading is

required for facilities aged

20-50 years old. Before upgrad-

ing it is rational to increase

observability of the facilities

through ensuring remote sig-

naling of switching devices and

telemetry on outgoing feeders;

• For relatively "young" substa-

tions aged 10-20 years, it is

possible to achieve a higher

level of digitalization by orga-

nizing digital return transmission

of remote measurement signals

from the Network Management

Center (signals transmission

can be ful

fi

lled by system opera-

tor or special-purpose software

package);

• The substations aged up to

10 years already have elements

of digital technologies. Automat-

ed control system organization

is the only task to accomplish

there;

• The substations under construc-

tion should be designed with the

use of modern power and sec-

ondary equipment and digital

data exchange based on IEC

61850 protocols.

Within the framework of the digi-

tal network implementation project,

four main digital technologies are

studied by ROSSETI Group:

1.

Network Management Center

(NMC).

Within the framework of

this direction, technologies de-

velopment for building a single

information system of operation-

al, technological and situational

management is under way. The

system should ensure network

model design, automated ope-

rational data collection at all

management levels and well-

founded and well-timed ma-

nagement decisions.

2.

Digital electrician.

Within the

framework of this direction, the

automated control over opera-

tional and repair personnel ac-

tions and the transformation

of document circulation into

digital form are introduced (us-

ing mobile digital devices). By

2030 it is planned to provide

each electrician with means of

augmented reality (all neces-

sary information for decision-

making will be displayed on the

protective shield of electrician's

helmet).

3.

Digital power distribution zone

(PDZ).

Within the framework of

this direction, basic commercial

technologies prototypes of the

target network business model

are tested through integrated

pilot projects. Also, economic

model is veri

fi

ed. All results are

used for subsequent replica-

tion. All these developments

are implemented in practice.

First results of electric networks

digitalization have shown that

ROSSETI Group is on the right

track.

For example, digital tech-

nologies implementation in the

Kaliningrad region (JSC "Yan-

tarenergo") in 2016 showed the

following positive effects:

– outages frequency and aver-

age power supply recovery

time were decreased;

– undersupply of energy was

reduced;

– power losses were reduced,

hence electricity payments

for ordinary consumers were

decreased.

4.

Digital substation.

Within the

framework of this direction, the

following works are carried out:

– determination of optimal di-

gital substation structure (in-

cluding individual systems of

the substation);

– statistics collection on equip-

ment reliability;

– personnel training, creation

of competence centers;

– international standards re-

view and domestic regulatory

documentation development.

For determining optimal digi-

tal substation structure, ROSSETI

Group have developed three types

of architecture:

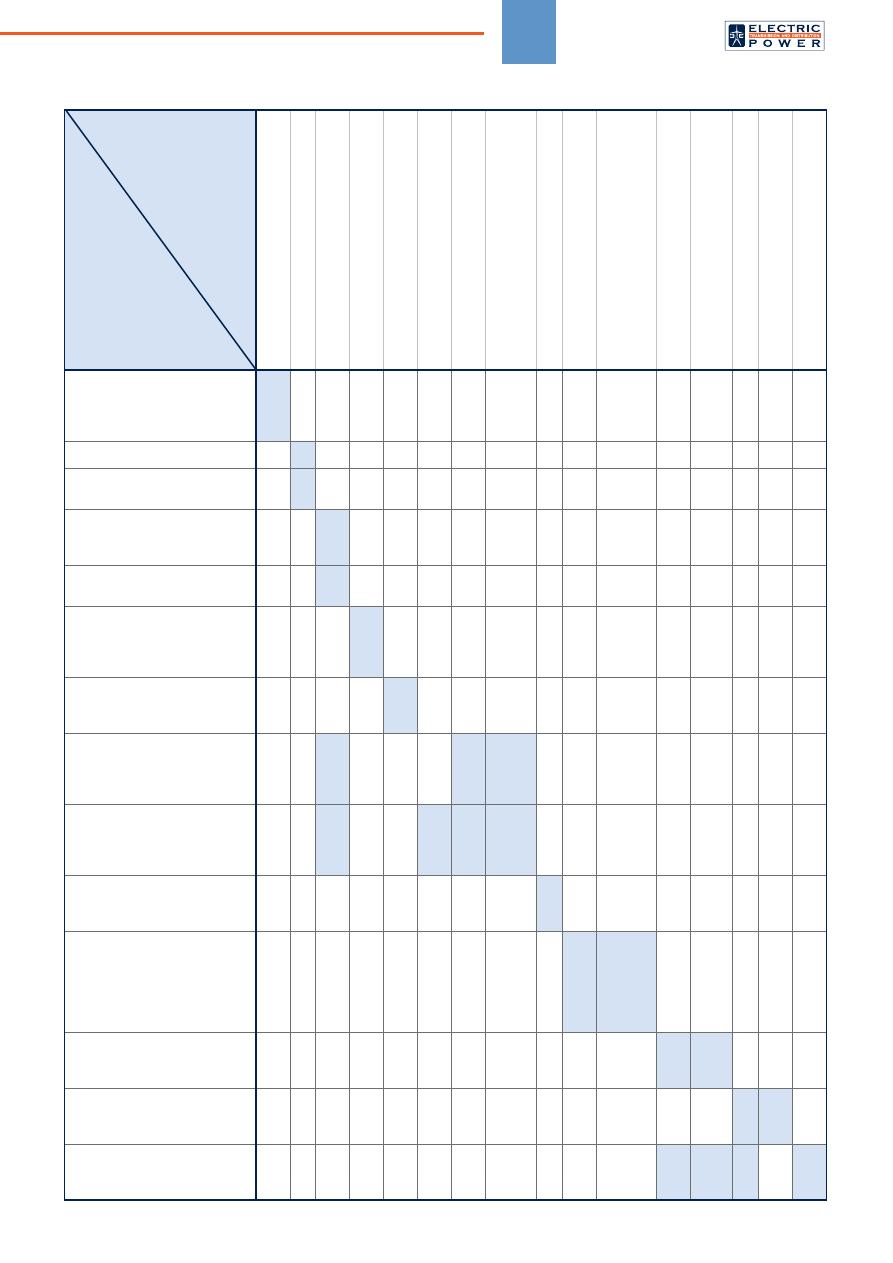

1) the

fi

rst type of architecture

(Figure 3) is characterized by

the following features:

– use of electromagnetic mea-

suring current transformers;

– transmission of analog data

without digitizing;

– discrete signals reception

and the transmission of

POWER GRIDS

DIGITALIZATION

Table 1. Digitalization level at substations of different generations

Year of substation

construction

Before 1970

1970-1989

1990-2009

After 2010

Number of 35 kV

substations and

above

3,523

10,183

2,057

622

Volume of works

The transition

to digital tech-

nology when

comprehensive

reconstructing

of substations

The transition to digital

technology when sub-

stations upgrading

Substations observability

enhancement until recon-

struction (implementation

of remote measurement

and signaling)

Observability enhancement (imple-

mentation of remote measurement

and signaling) – digital data trans-

mission to Network Management

Center

Implementation of telecontrol with

automatic control system orga-

nizing (IEC Standard)

Substations al-

ready have ele-

ments of digital

technology

There is a need

to organize an

automatic con-

trol system

27

Table 2. Matrix of technical solutions

Operating

equipment

with manual

control and analog

data transmission

Operational information management

system, SCADA

(CIM)

Digital meters

Digital data acquisition and transmission

devices

Microprocessor-based relay protection and

automation with IEC protocol support

Microprocessor-based telemechanics with

IEC protocol support

Digital communication equipment (commu- nication through high-frequency channel)

Digital communication equipment (cellular

and radio communication)

Digital communication equipment (commu- nication through

fi

ber optic communication

line)

Sectionalizing points / reclosers

Measuring transformers with SF6 gas

insulation and cast insulation

Measuring transformers with SF6 gas

insulation and cast insulation and analog

converters or digital measuring trans- formers

High-voltage vacuum circuit breakers or

SF6 circuit breakers

High-voltage vacuum circuit breakers or

SF6 circuit breakers with digital transducers

Remote control drive

Disconnectors and grounding blades with

motor drive

6-35 kV load break switches with motor

drive

Substations not provided

with software and hardware

for equipment display and

control

Induction meters

Electronic meters without

remote data collection

Data acquisition and trans-

mission devices without sup-

porting IEC protocol

Lack of data acquisition and

transmission devices

Relay protection and automa-

tion based on electrome-

chanical and microelectronic

elements

Telemechanics based on

electromechanical and micro-

electronic elements

Analog communication

equipment (communication

through cable communication

line)

Analog communication

equipment (communica-

tion through high-frequency

channel)

Necessity of 6-35 kV electri-

cal network sectioning (power

transmission lines)

Measuring transformers not

satisfying metrological re-

quirements (accuracy class,

transformation ratio, rated

power, number of secondary

windings, etc.)

High-voltage circuit breakers

not providing control and

monitoring functions

Disconnectors and grounding

blades not providing control

and monitoring functions

6-35 kV load break switches

not providing monitoring

function

Installed equipment

with remote control

and digital data

transmission

47th CIGRE Session

Special issue, August 2018

28

control signals to switching

devices without digitizing;

– use of IEC 61860-8.1

GOOSE station bus for com-

munication with Automa

tic

Process Control System

(APCS);

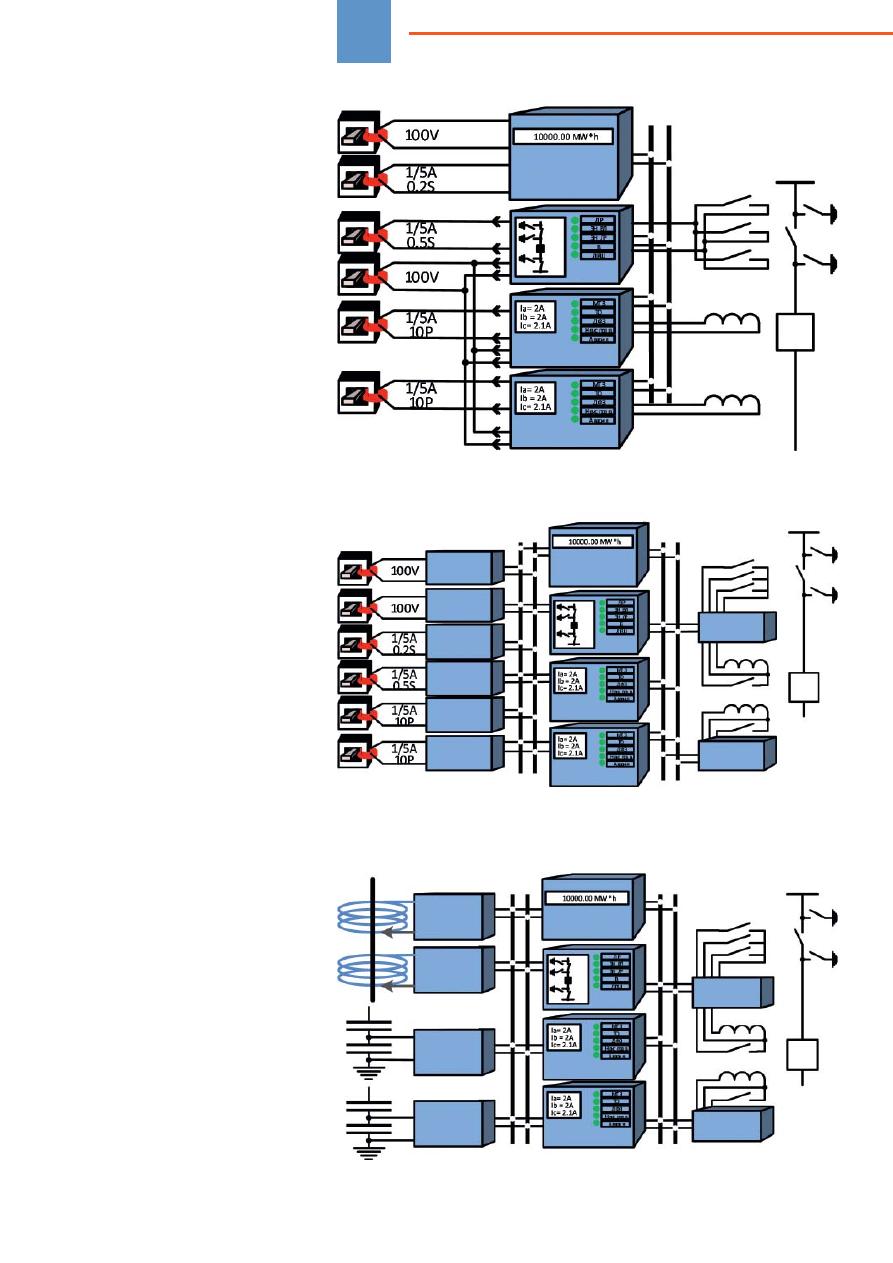

2) the second type of architecture

(Figure 4) is characterized by

the following features:

– use of electromagnetic mea-

suring current transformers;

– conversion of analog data

into digital format according

to IEC 61850-9.2 SV pro-

tocol;

– transmission of analog sig-

nals to the substation auto-

mation devices via process

bus in the format of IEC

61850-9.2 SV protocol;

– conversion of discrete

signals into digital format

according to IEC 61860-8.1

GOOSE protocol;

– transfer of discrete signals

to the substation automation

devices via station bus in

the format of IEC 61850-8.1

GOOSE, MMS protocol;

3) the third type of architecture

(Fi gure 5) is characterized by

the following features:

– use of digital measuring

transformers generating digi-

tal data in accordance with

IEC 61850-9.2 SV protocol;

– transmission of analog sig-

nals to the substation auto-

mation devices via process

bus in the format of IEC

61850-9.2 SV protocol;

– conversion of discrete signals

into digital format according

to IEC 61860-8.1 GOOSE

protocol;

– transfer of discrete signals

to the substation automation

devices via station bus in

the format of IEC 61850-8.1

GOOSE, MMS protocol;

The choice of digital substa-

tion architecture depends on sub-

station layout complexity, number

and type of equipment. It is obvious

that small single-transformer sub-

stations shouldn’t be digitized ac-

cording to architecture no. 3. In this

case architectures no. 1 or no. 2

are convenient options. The maxi-

mum effect from architecture no. 3

Figure 5. Architecture of digital substation type no. 3

Figure 3. Architecture of digital substation type no. 1

IEC 61860-8.1

GOOSE station bus

Automated power

consumption

measurement

system

Teleme-

chanics

Circuit breaker

opening/closing

solenoids

Circuit breaker

opening solenoid 2

Relay protection

and automation 1

Relay protection

and automation 2

Figure 4. Architecture of digital substation type no. 2 (SHS – software/hardware

system; VT – voltage transformer,

С

T –

с

urrent transformer)

IEC 61850-8.1

GOOSE, MMS

station bus

IEC 61850-9.2

SV process

bus

Automated power

consumption mea-

su rement system

Digital merging

unit 1

Digital merging

unit 2

SHS

(VT for

capa citor unit)

SHS

(CT for

capa citor unit)

SHS

(VT for

relay protection

and automation)

SHS

(CT for

telemechanics)

SHS 1

(CT for

relay protection

and automation)

SHS 2

(CT for

relay protection

and automation)

Teleme-

chanics

Circuit breaker open-

ing/closing solenoids

Circuit breaker

opening solenoid 2

Relay protection

and automation 1

Relay protection

and automation 2

IEC 61850-8.1

GOOSE, MMS

station bus

IEC 61850-9.2

SV process

bus

Automated power

consumption mea-

su rement system

Digital

merging unit 1

Digital

merging unit 2

Digital

current

transformer 1

Digital

voltage

transformer 1

Digital

current

transformer 2

Digital

voltage

transformer 2

Teleme-

chanics

Circuit breaker open-

ing/closing solenoids

Circuit breaker

opening solenoid 2

Relay protection

and automation 1

Relay protection

and automation 2

POWER GRIDS

DIGITALIZATION

29

Table 3. ROSSETI Group digital substations projects under realization

Number

of sub-

stations

Digital

technology

Characteristics

Subsidiaries and af

fi

liates

Fully digital

substations

4 sub-

stations

(under way)

Digital

substations

Support

IEC 61850-8.1/9.2,

IEC 60870-5-104

PJSC "MOESK"

(110 kV "Medvedevskaya" sub station);

PJSC "IDGC of North-West"

(110 kV "Yuzhnaya"

substation);

PJSC "Kubanenergo"

(110 kV "Tuapse-

gorod" substation);

PJSC "IDGC of Centre"

(110 kV

"Stroitel" substation)

Pilot

implementation

of certain

digital

substation

technologies

4 sub-

stations

Digital relay

protection,

Digital automatic

process control

system

Support

IEC 61850-8.1/9.2,

IEC 60870-5-104

JSC "Tyumenenergo"

(110 kV "Olimpiyskaya"

substation);

PJSC "IDGC of Siberia"

(110 kV

substation named after M. Smorgunov);

PJSC "MOESK"

(35 kV "Babayki" substation);

PJSC FGC UES

(110 kV substation no. 301)

1 sub station

1 substation

(under way)

Digital

measuring

transformers

Support

IEC 61850-9.2

PJSC FGC UES

(110 kV substation no. 301);

PJSC FGC UES

(500 kV "Tobol" substation)

Industrial

application of

certain digital

substation

technologies

35 sub-

stations

Digital automatic

process control

system

Support

IEC 61850-8.1

PJSC FGC UES; JSC "Yantarenergo"; JSC "Tyumen-

energo"; PJSC "IDGC of Centre"; PJSC "MOESK";

PJSC "IDGC of the South"; PJSC "IDGC of Volga"

More than

1000 sub-

stations

Data collection

and transmission

system

Support

IEC 60870-5-104

All subsidiaries and af

fi

liates

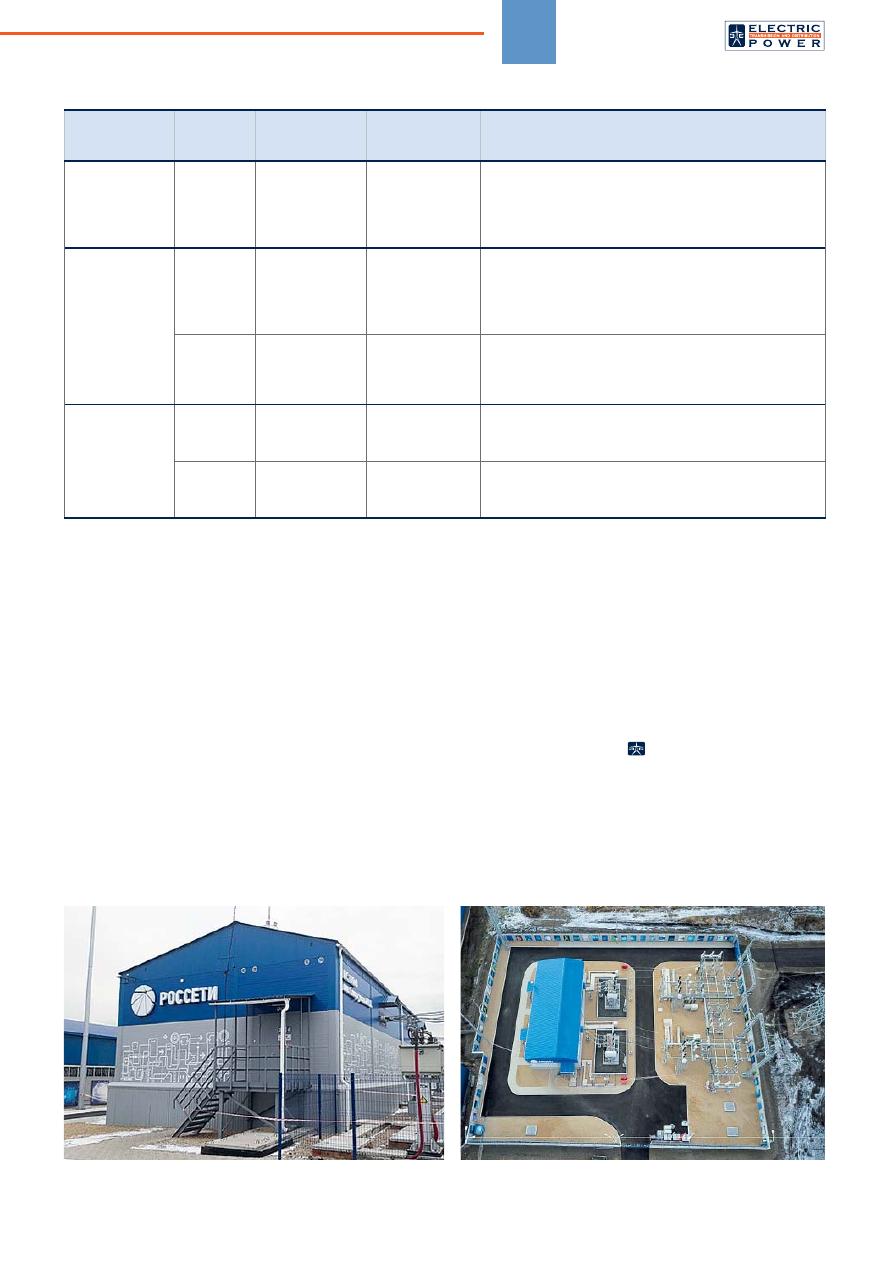

Figure 6. 110 kV substation named after M. Smorgunov with digital control system

application can be achieved at sub-

stations with several transformers,

complicated connection layout and

a large number of connections.

ROSSETI Group implements

digitalization pilot projects with vari-

ous types of architectures and sub-

stations in order to determine the

criteria for choosing digital substa-

tions architecture.

It should be noted that ROSSETI

Group has already implemented

substations using local digital so-

lutions. Such substations provide

power supply of Moscow Energy

Ring and Winter Olympics facili-

ties in Sochi. In addition, a number

of digital substations projects with

various architectures (no. 2 and

no. 3) have been implemented for

testing design decisions and gain-

ing operation experience. 110 kV

substation named after M. Smor-

gunov with digital control system

according to architecture no. 2 was

put into operation in December

2017 in Krasnoyarsk.

500 kV digital switching "Tobol"

substation using data transmission

in accordance with architecture no.

3 was put into operation in the Tyu-

men Region in 2018. The similar

facilities were also built in the Mos-

cow region.

Eventually, ROSSETI Group in-

tends to carry out power grid digital

transformation by 2030. It allows

ROSSETI Group to get manage-

able, intelligent electric grid with

a high level of power supply reliabil-

ity and a number of positive internal

effects.

The creation of digital networks,

even according to the most cau-

tious forecasts, will result in reduc-

tion power losses, capital expendi-

tures and operating expenses by

30%. SAIDI and SAIFI reliability

indicators should be improved by

50%.

REFERENCES

1. Livinsky P.A., Gvozdev D.B. Inno-

vative power system of Russia in

2050. Energeticheskaya politika

[Energy Policy], 2017, no. 6. pp. 16-

19. (in Russian)

47th CIGRE Session

Special issue, August 2018

Оригинал статьи: Development of Cooperation in Power Industry

Russian companies actively work to set up interstate integration with power engineers and electrical engineering companies of the world. The most important targets of the work are European countries and rapidly developing regions of Asia.